The plastic chair making machine provided by YG can produce various shapes of plastic chairs by changing the mold. The plastic bench is directly manufactured by an injection molding machine. Plastic chairs are usually made of PP or ABS materials. The produced plastic chairs are small in size, light in weight, strong in impact resistance, and durable. YG plastic chair molding machine manufacturers not only provide injection molding equipment but also support custom plastic chair molds. Please tell us your needs, we will customize a solution for you according to your needs.

Plastic Chair Finished Product Display

YG machines can produce a wide variety of plastic chairs with different shapes, sizes, and styles:

- Small chairs for children – lightweight, durable, and safe for kids.

- Standard dining and office chairs – strong, stackable, and suitable for home or commercial use.

- Large benches and outdoor chairs – sturdy for gardens, patios, and public spaces.

- Modern designer chairs – sleek shapes with smooth surfaces, available in white or transparent colors for a stylish look.

- Custom-shaped chairs – molded to meet unique designs or ergonomic requirements.

All finished chairs are impact-resistant, durable, and smooth-finished, making them ideal for industrial, commercial, and residential applications.

What is the Material Used to Make the Plastic Chair?

The material of plastic chairs is generally PP, and high-end chairs generally use ABS materials. In addition, it can also use PC, PS, PE, PET, and HDPE materials.

PP is a semi-crystalline thermoplastic and one of the lightest varieties of plastics. It has high impact resistance, strong mechanical properties, resistance to various organic solvents, and acid and alkali corrosion. The finished plastic chair made of plastic material has good processing performance and is strong and durable.

ABS resin is one of the five major synthetic resins and is a very versatile thermoplastic engineering plastic. It is widely used in machinery, automobiles, electronic appliances, textiles, construction, and other fields. Because ABS resin has the characteristics of very good impact resistance, heat resistance, easy processing, and good surface gloss, it is usually used to make high-grade plastic chairs.

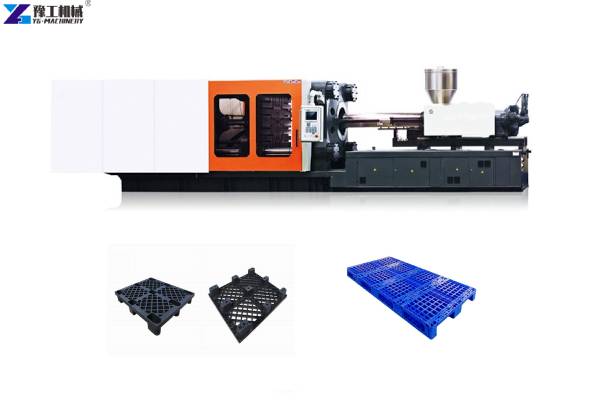

How are Plastic Chairs Made?

Plastic chairs are direct injection molded using an injection molding machine. A plastic injection molding machine is a device that processes thermoplastic or thermosetting plastics through a mold. Before using the injection molding machine to process the plastic raw materials, you first need to customize the plastic chair molds of different shapes. The thermoplastic or thermoset material is then processed through an injection molding machine into a chair that has the shape of the mold.

Plastic Chair Making Machine Price

The price of a Plastic Chair Making Machine depends on machine size, clamping force, injection volume, and mold configuration. For reference:

- Small chairs (children chairs, home chairs): USD 25,000–50,000

- Medium chairs (office, dining chairs): USD 50,000–120,000

- Large chairs & benches (long benches, outdoor chairs): USD 120,000–300,000

Higher capacity machines or fully automated systems cost more. Custom molds and high-precision machines will also increase the price.

Brazil Case Example

A Brazilian furniture manufacturer purchased a 120T Plastic Chair Injection Molding Machine for office chair production. The machine produces 500 chairs per day, with PP material, and includes a custom 4-cavity mold. This setup reduced production cost by 15% compared to manual methods, and the customer successfully expanded into local commercial sales.

If you want a price recommendation for your chair project, tell us your chair type, material, and daily output, and YG will provide a tailored solution.

Common Plastic Chair Injection Molding Machine Parameters

| Machine Type | Plastic Chair Injection Molding Machine |

| Shot Volume | 200–600 g |

| Screw Diameter | 40–60 mm |

| Injection Pressure | 150–200 MPa |

| Clamping Force | 108–220 T |

| Motor Power | 15–45 kW |

| Screw Speed | 0–180 rpm |

| Tonnage Range | 100–220 T |

These parameters cover most small, medium, and large chair production requirements. Custom configurations are available.

FAQ about plastic chair production line

Q: How much does a plastic chair making machine cost?

A: Prices range from USD 25,000 to 300,000, depending on machine capacity, clamping force, mold design, and automation level.

Q: Can one machine produce multiple chair types?

A: Yes, changing the mold allows one injection molding machine to produce chairs of various designs and sizes.

Q: What materials are suitable for plastic chair production?

A: PP and ABS are the most common; PC, PS, PE, PET, and HDPE can also be used.

Q: Does the price include molds?

A: Molds are usually quoted separately; cost depends on chair design, cavity number, and steel quality.

Q: How do I choose the right machine for my production?

A: Provide chair type, material, and daily output, and YG will recommend the optimal machine and price range.

Dear HENAN YG Plastic Machinery,

I am delighted to confirm with interest to purchase your machines plant for the production of both:

– Plastic chairs.

– Plastic bukests

– Public Garage Buckets etc..

Thank you for responding

Hello friend, thank you for your inquiry.

May i know your whatsapp number? Or you can add my whatsapp number +86 15037187716.

Expect your early reply.