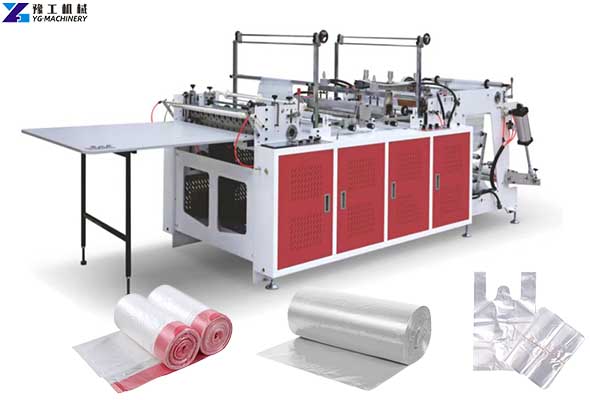

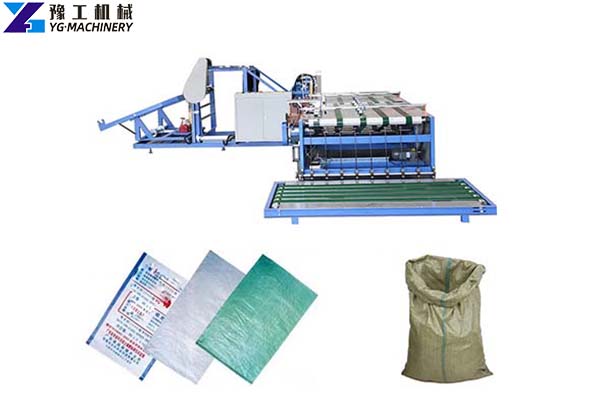

The air column bag making machine is a special equipment for producing cushioning air column bags of new packaging materials. It uses various PE co-extrusion films and other raw materials to make cushion bags through the A+B buffer air column bag forming machine. The produced air column bags have strong pressure resistance and are used in the packaging of various fragile products and electronic products. YG plastic processing machinery manufacturer provides plastic bag-making machines, plastic film-blowing machines, and other equipment. If you are interested in a buffer air column bag forming machine, please contact us.

Buffer Air Column Bag Making Machine Overview

Raw material: The raw material is a co-extruded film, and the co-extruded film should reach more than five layers, seven layers, nine layers, and eleven layers are all available.

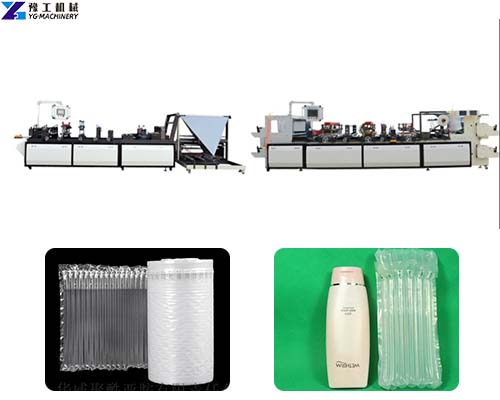

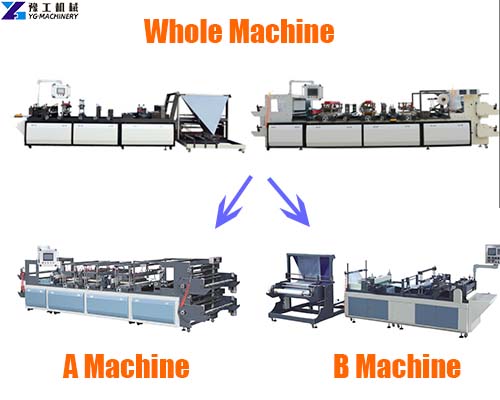

Equipment: buffer air column A machine, buffer air column bag B machine.

Finished product: air column packaging bag.

Auxiliary equipment: cooling tower and mixer, optional according to customer needs.

Applicable fields of finished product packaging: used for packaging fruit juice drinks, skin care products, tobacco and wine, electronic products, fruits and vegetables, and other fields.

Finished Product Display

Air Column Bag Forming Machine Composition

The air column bag forming machine mainly includes two parts: A buffer cushion bag manufacturing equipment and B buffer air cushion bag forming machine. The two sets of equipment can be used together to produce air column bags through certain steps.

| Model | buffer air column A machine |

| Max. film width | 1200mm |

| Film thickness | 0.02-0.20+mm |

| Suitable material | PE co-extrusion film, PE low-pressure film, etc. |

| Forming speed | 18-36m/min(The speed is related to the thickness of the film and the material) |

| Air valve film sealing pressure | 7560N |

| Column channel sealing pressure | 395mm |

| Max. feeding film roll diameter | Φ600mm |

| Max. winding film roll diameter | Φ600mm |

| Feeding&winding air shaft diameter | Φ74mm |

| Air pressure | 0.6-0.8MPa |

| Air consumption | 0.8m3/min |

| Machine noise | 55db |

| Rated power | 18kw |

| Power supply | AC 380V, 50Hz three-phase four-wires |

| Machine weight | About3.8T |

| dimension | L6860×W1800×H1900mm |

| Model | buffer air column bag B machine |

| Max. Film Width | 1200mm |

| Max. Bag Width | 800mm |

| Max. Film Roller Diameter | Φ600mm |

| Shafts Diameter | Φ74mm |

| Film Material | PE co-extrusion film |

| Bag Making Speed | 60-120 Times/Min (Depending On Different Design |

| Edge Seal Sealing Pressure | 2000N |

| Edge Seal Width | 600mm |

| Machine Noise | 55db |

| Air Pressure | 0.68Mpa |

| Air Consumption | 0.8m3 /Min |

| Rated Power | 5kw |

| Power Supply | Ac 380V,50Hz Three-Phase, Four-Wires |

| Weight | About 2.8T |

| Dimension | L3980mm×W1300mm×H1800mm |

The above are the parameters of the A+B air column bag making machine. If you want to know the air column bag making machine price, please leave us a message.

Advantages Of Cushioning Air Column Bag Packaging

Buffer air column bag is a new type of packaging material filled with natural air. The packaged items are protected by an air-filled air column buffer, which minimizes the loss rate of product transportation. Therefore, the air column bag has a very wide range of applications. At present, it has been widely used in small household appliances, wine, musical instruments, electronic products, fruits and vegetables, fresh food, and other fields. Buffer air column packaging has the advantages of cushioning, shockproof, protection, and quick use.

Features Of Air Column Bag Making Machine

- Adopt imported PLC and inverter joint control, good man-machine interface, easy to operate.

- The temperature control module clears the paper tube, and the high-performance line sensor is used for feeding and unwinding, which can continuously and stably unwind the material.

- Rewinding and unwinding adopts an air-expanding shaft structure, which is convenient for loading and unloading

- In addition, the machine has automatic counting, alarm, shutdown, and other functions.

- The finished product of the air cushion machine is of good quality and high output.

- This whole machine is controlled by a frequency converter, with a wide frequency conversion range and large speed adjustment range, realizing wireless speed change.

- The main click adopts a motor deceleration and brake integrated machine, no belt and chain connection, no noise, stability, and high precision.

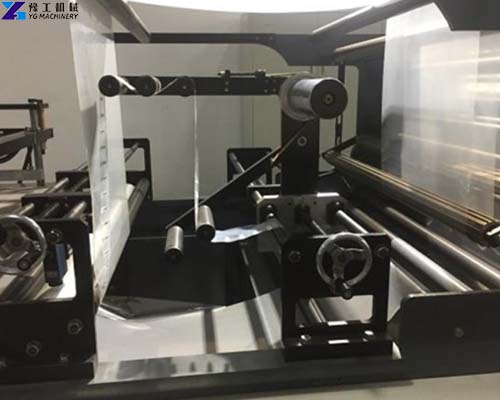

Machine Details Display