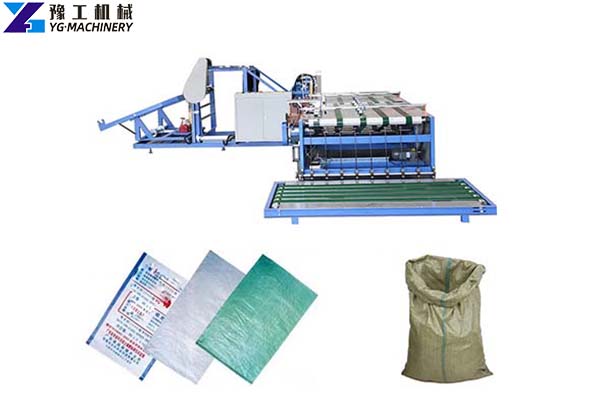

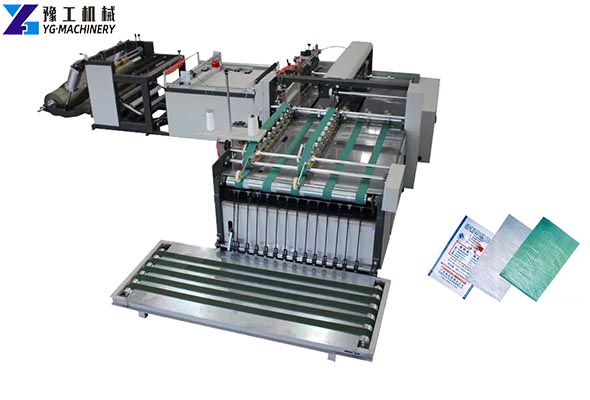

The PP bag printing machine is a kind of printing machine, that is used for printing text and pictures on woven bags. It is a device for printing the required text and trademark patterns on the surface of the cut semi-finished woven cloth. YG PP bag printing machine manufacturer provides 1~6 colors woven sack printing machine for your reference. The machine has the characteristics of continuous printing, one-time printing forming, stable operation, and so on. It is the best equipment for printing woven bags, bulk bags, container bags, etc. Also, it can equip with the PP woven bag making machine( wire drawing machine, circular loom cutting machine, sewing machine) to form a line.

Woven Bag Printer Machine Working Video

Parameters of Woven Sack Printing Machine

| Model | YG-840Ⅱ | YG-840Ⅲ | YG-840Ⅳ |

| Most greatly entering machine width | 800mm | 800mm | 800mm |

| Maximum printing width | 650mm | 650mm | 650mm |

| Rubber relief printing thickness | 4-6mm | 4-6mm | 4-6mm |

| Biggest printing length | 1200mm | 1200mm | 1200mm |

| India roller diameter | 430mm | 430mm | 430mm |

| Printing color | 1500-3500pcs/h | 1500-3500pcs/h | 1500-3500pcs/h |

| Printing color | 1 Color | 2 Color | 3 Color |

| Electrical machinery power | 0.75kw | 1.5kw | 1.5kw |

| Installs the size | 900*1400*1200 | 1400*1400*1200 | 2000*1400*1200 |

| Gross weight(approximate | 1500kg | 2000kg | 2500kg |

PP Bag Printing Machine Application

The PP bag printing machine is a kind of equipment for printing patterns on woven cloth or other raw materials. It is suitable for surface printing of semi-finished woven cloth, woven cloth ton bags, container bags, mattress packaging bags, sofa packaging bags, wallpaper wall coverings, etc. In recent years, woven bags used in food packaging, industry, transportation, and other industries are very popular. Therefore, woven bag printing machines are gradually becoming more and more popular.

Remarks: YG provides woven sack printing machines for 1~6 color printing.

How does the PP Bag Printing Machine Work?

The plastic woven bag printing machine first makes the printed text and image into a printing plate and installs it on the printer, and the printing machine directly prints the printing plate on the article. The PP bag printing machine goes through feeding, positioning, plate dropping, lowering to the inked plate, lifting back to the inked plate, scraping stroke, raising to the inked plate, lowering back to the inked plate, lifting the plate, returning to the ink stroke, relocating, receiving and other cycle processes to complete the printing work. The whole set of actions greatly shortens the running time and improves the production efficiency under the operation of the computer control panel.

How to choose the Suitable PP Woven Bag Printing Machine?

If you want to buy a woven bag printer, you need to know what product you need to print. Then determine the maximum width and length of the printed product. Choose the right model of the machine according to the length and width of the printed product. Generally speaking, you can choose equipment according to the width, and the models of printing machines are divided into 800mm, 1000mm, and 1200mm according to the width. Moreover, YG PP woven bag printing machine manufacturers can also customize the machine according to customer needs, and the maximum width that can be customized can reach 3m.

Woven Sack Printing Machine Features

- The machine runs smoothly, with advanced design, high production efficiency, and long service life.

- Reasonable mechanism design, convenient adjustment, fast printing, one-time molding, and convenient maintenance.

- Widely used in woven bag printing in the food packaging industry, transportation industry, industry, and other fields.

- Even ink transfer, full black, clear printing effect, saving ink.

- Electronic tracking, computer counting, and infrared positioning are more convenient to replace ink.

- The printing roller is automatically tracked and separated, and the ink transfer roller and the printing plate can be separated.

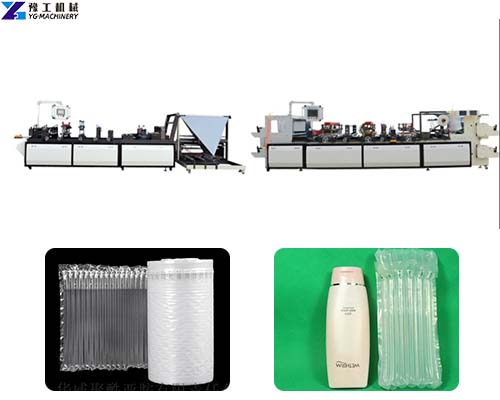

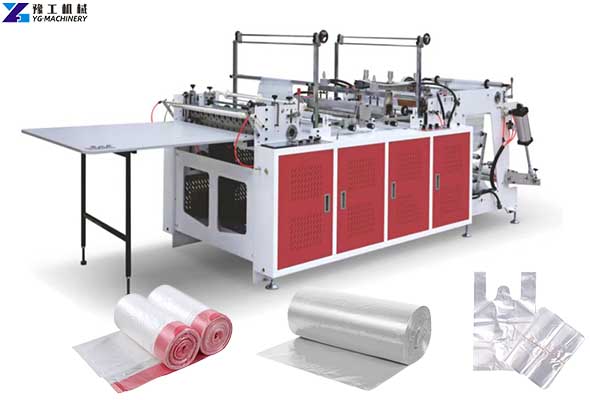

Related equipment recommendation from YG

Besides PP Bag Printing Machine, we also produce plastic film flexo printing machines. This machine can focus on printing PE plastic bags, paper bags, non-woven bags, paper cups printing, etc. Therefore, the plastic bag printing machine can also be combined with a small plastic bag making machine to produce a plastic bag with the pattern. We also have all the equipment from making raw materials to finished plastic bags. If you need it, contact us, YG will provide you with a detailed quotation!