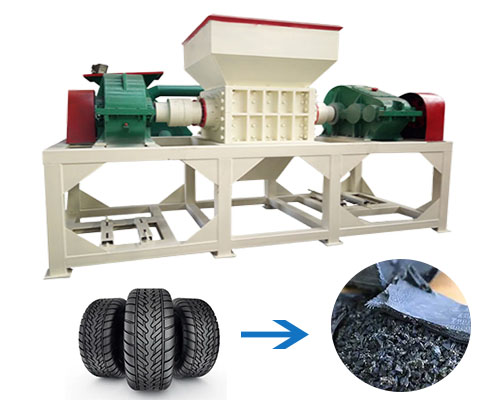

The tire shredding machine (scrap plastic rubber shredder machine) is a crushing equipment for recycling plastic and rubber. The machine mainly achieves the purpose of reducing the size of the material through cutting, shredding, and extrusion. The rubber tire shredding machine can shred scrap metal, scrap iron, wood, construction waste, cardboard, and other raw materials. Therefore, waste tyre shredders are widely used in the waste recycling industry, garbage treatment, solid waste, hazardous waste treatment, and other industries. A scrap tire shredder is the shredding device in waste tire recycling lines.

Rubber Tire Shredding Machine Parameters

| Model | Tool Specifications | Power | Number of tools | Reducer | Rotating speed(r/min) | Size(m) |

| 200A | Φ180*12 | 2.2KW | 18 | 200 | 16-24 | 0.8*0.5*1.3 |

| 200B | Φ180*15 | 2.2KW | 18 | 200 | 16-24 | 1.0*0.5*1.45 |

| 300A | Φ180*15 | 3KW | 28 | 240 | 16-24 | 1.2*0.6*1.55 |

| 300B | Φ180*20 | 3KW | 25 | 240 | 16-24 | 1.3*0.65*1.6 |

| 400A | Φ200*10 | 4KW | 32 | 320 | 16-24 | 1.35*0.65*1.8 |

| 400B | Φ200*15 | 4KW | 28 | 320 | 16-24 | 1.4*0.7*1.85 |

| 500A | Φ200*10 | 7.5KW | 40 | 400 | 16-24 | 1.4*0.68*1.9 |

| 500B | Φ200*20 | 7.5KW | 20 | 400 | 16-24 | 1.45*0.75*2.0 |

| 600A | Φ200*10 | 15KW | 48 | 400 | 18-25 | 1.45*0.87*2.2 |

| 600B | Φ200*20 | 15KW | 24 | 400 | 18-25 | 1.45*0.87*2.2 |

| 800A | Φ200*20 | 15KW*2 | 32 | 400*2 | 18-25 | 2.15*0.87*2.2 |

| 800B | Φ300*30 | 30KW*2 | 18 | 650*2 | 18-25 | 3.4*1.2*2.2 |

| 1000A | Φ300*25 | 30KW*2 | 32 | 650*2 | 18-25 | 3.4*1.25*2.2 |

| 1000B | Φ300*30 | 30KW*2 | 27 | 650*2 | 18-25 | 3.4*1.25*2.2 |

| 1000C | Φ400*40 | 45KW*2 | 20 | 750*2 | 18-25 | 3.4*1.25*2.2 |

| 1200A | Φ400*30 | 55KW*2 | 38 | 650*2 | 18-25 | 4.15*1.25*2.2 |

| 1200B | Φ400*40 | 55KW*2 | 28 | 750*2 | 18-25 | 4.15*1.25*2.2 |

| 1500A | Φ400*30 | 75KW*2 | 48 | 750*2 | 18-25 | 4.15*1.25*2.2 |

| 1500B | Φ400*40 | 75KW*2 | 36 | 750*2 | 18-25 | 4.15*1.25*2.2 |

| 1500C | Φ400*50 | 75KW*2 | 28 | 850*2 | 18-25 | 4.15*1.25*2.2 |

| 2000A | Φ530*50 | 90KW*2 | 38 | 850*2 | 18-25 | 5.25*1.78*2.2 |

| 2000B | Φ600*60 | 90KW*2 | 31 | 850*2 | 18-25 | 5.25*1.78*2.2 |

Plastic & Rubber Shredding Machine Application

Scrap tires: car tires, truck tires

Pipes: large pipes, pipe fittings, PE pipes

Waste home appliances: TV sets, washing machines, refrigerator shells

Waste templates: wooden pallets, plastic pallets, forklift pallets

Scrap metal: car shell, aluminum alloy, scrap aluminum casting

Hollow containers: plastic beverage cans, plastic cylinders, iron drums, etc.

Household waste, kitchen waste, animal carcasses, medical waste, etc.

Overview of Tyre Shredding Machine

Function: Cut and shred bulky materials that are inconvenient to transport into materials that meet the size requirements.

Crushing size: YG can customize the size of the blade to help you make different crushed material sizes.

Components: Shredding blade group, box body, bracket, feeding system, power system, electrical control system.

Scope of application: Widely used for shredding scrap metal, plastic and rubber products, domestic waste, medical waste, etc.

Machine model: single-shaft, double-shaft, four-shaft shredder

Types of Rubber Shredding Machine

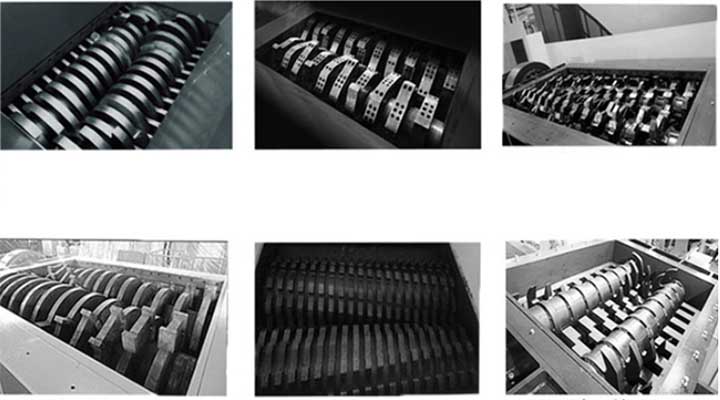

The rubber shredding machine mainly relies on the internal knife roller to cut, shred, and squeeze to reduce the size of the material. Therefore, according to the type of internal knife roller, there are mainly four types of tire shredders, which are single-shaft, double-shaft, four-shaft, and coarse crushing tire shredders.

Single-shaft Tire Shredder

The single-shaft tire shredding machine mainly uses the interaction between the moving knife and the fixed knife to control the output size through the screen. And it is often the primary crushing of various plastic solid wastes, which can process the materials into smaller sizes at one time. The single-shaft shredder can shred plastic, machine head material, film, agricultural film, PP woven bags, ton bags, PE bottles, foam, etc.

Double Shaft Shredder

The twin-shaft shredder uses two shafts to shear, squeeze and tear the material, which solves the problem of recycling hard and hollow materials. So the double-shaft shredder is especially suitable for shredding waste household appliances, scrap metal, rubber tires, packaging barrels, scrap cars, etc.

Four Shaft Shredder

The blades of the four-axis scrap tire shredder are distributed in a V-shaped spiral, and the force is more uniform. The auxiliary knife has the function of automatically cleaning the main knife. A four-shaft tyre shredding machine handles greater throughput, and it can handle stronger solid waste that a two-shaft shredder cannot handle. Such as bulky waste, medical waste, leather scraps, waste wood, animal carcasses, solid waste, etc.

Working Principle of Tire Shredding Machine

The tire shredding machine adopts a geared motor. We connected it to the worm gear directly, which is directly installed on the drive shaft of the shredder, and the speed is changed to the transmission shaft through the size. The helical-toothed cutter head on the main drive shaft moves relative to each other. After the material enters, it is simultaneously squeezed, shredded, and sheared. Therefore, the material is crushed.

Features of Waste Tire Shredder

Wide application

It can shred scrap metal, domestic and medical waste, pipes, wood, large rolls of film, vats, etc.

High-performance knives

The raw materials of the knives are made of imported alloy steel, which has high wear resistance, is strong, and has a long service life.

Optional drive system

YG provides optional electric and hydraulic motor drive systems. The entire power system is designed for low speed, high torque, and strong crushing capacity.

Good crushing effect

The tire shredding machine has single-shaft, double-shaft, four-shaft, and other structural equipment options. The equipment has the characteristics of low noise, high torque, and good crushing effect.

Customize the crushing size

We can change the thickness of the cutter and the number of claws according to different materials. So the crushing size can be customized.

About Tire Shredding and Recycling

Waste tires are rubber products, which are difficult to degrade waste, and can be used after recycling. There are two recycling methods for waste rubber: direct utilization and indirect utilization. The direct use method is to use the original shape or almost the original shape. And for example, tire refurbishment, fenders, and vehicles, track buffer materials, lifebuoys, playgrounds, sports facilities materials, lighthouses, etc. Indirect utilization is the utilization of rubber tires after chemical or physical processing. The processed rubber can be recycled into rubber powder, recycled rubber, used as rubber concrete, asphalt modifier, cracked, and recycled.

Why Use Tyre Shredding Machine?

- High crushing efficiency: tire shredder can quickly cut and tear waste tires into small pieces, greatly improving processing efficiency.

- Wide processing range: tyre shredding machine can process all kinds of waste tires, whether it is car tires, motorcycle tires, or truck tires, tire shredder can effectively crush them.

- Easy to follow-up treatment: shredded tire fragments are easier to carry out subsequent processing, such as granulation, grinding, etc.

- Reduce transportation costs: we can reduce the volume of tires after tearing waste tires into small pieces. Thus users can reduce the transportation cost.

- Reduce environmental pollution: Using tire shredders for recycling and reuse can effectively reduce pollution to the environment.

- It is conducive to resource reuse: we can use rubber particles, and rubber powder in runway construction, asphalt modification, rubber manufacturing, and other fields.

Tire Shredders Recycling Production Line

Tire shredders can work with other equipment to form a tire recycling production line. The tire recycling production line can process the entire waste tire into rubber blocks and rubber powder of different sizes. These equipments are:

In addition to this equipment, tire wire drawing machine, tire cutting machine, tire shredder, rubber powder machine, rubber powder machine, nylon winnowing machine, etc. YG can also provide other alternative tire recycling solutions. We will recommend a suitable tire recycling production line combination according to your budget and output.

The following is the composition of the tire recycling line:

Application Scope of Processed Waste Tires

- The processed waste rubber is generally granules or powders. Such materials are suitable for producing recycled rubber, rubber flooring, rubber coatings, and other products. These products also have high economic value.

- Refining: We can get oil after high-temperature dissolution and cooling treatments.

- Carbon black utilization: We can burn the tire to produce the carbon black. It is the raw material for manufacturing plastic runways.