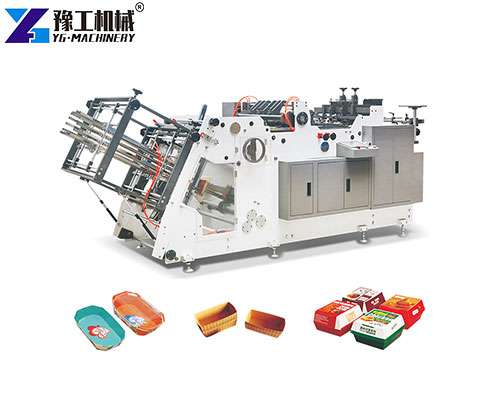

Recently, a Mexican client purchased a hamburger box making machine from YG Machinery to expand their food packaging production line. As the fast food industry grows in Mexico, the demand for eco-friendly paper burger boxes has surged. Local restaurants and fast food chains are seeking efficient, automated solutions to produce high-quality disposable packaging. This client aimed to upgrade their production capabilities and meet the rising market need for sustainable food containers.

hamburger box making machine Parameters

| Model | YG-800 | YG-C800 | YG-S800 | |

| Paper Cup Size | 3-16OZ | 3-16OZ | 3-16OZ | |

| Raw Material | One-side PE | One-side PE | One-side or two-side PE-coated paper (Singe PE or Double PE coated paper) | |

| Speed | 65-75 pcs/min | 70-80 pcs/min | 75-85 pcs/min | |

| Suitable paper weight | 150-180g;±20g | 150-300g;±20g | 160-300g/;±20g | |

| Voltage supply | 380V, 50HZ | 380V, 50HZ | 380V(220V) 50HZ | |

| cup size | Bottom35-70mm, Top45-90mm High32-135mm | Bottom35-70mm,Top45-90mm, High32-135mm | Bottom35-70mm, Top45-90mm, High32-135mm | |

| General power | 4.5 kW | 5 kW | 6 kW | |

| Working Air Source | NO | NO | 0.4-0.6Mpa; 0.4m3/min | |

| Net weight | 1680kg | 1680kg | 2000kg | |

| Measurement (mm) | L:2115mm;W:1000mm;H:1700mm | L:2115mm;W:1000mm;H:1700mm | Main engine | L:2100mm;W:1200mm;H:1800mm |

| Cup holder | L:900mm;W:600mm;H:1500mm | |||

| Cup Side Sealing | Copper bar heating | Evergreen Ultrasonic | Evergreen Ultrasonic | |

| Bottom Knurling | Heating | Heating | Hot Air System | |

| We can customize the machine and mold according to the customer’s requirements. Also, we have a high-speed machine, 100-120pcs/min. | ||||

Mexico’s Growing Demand for Paper Burger Boxes

Mexico’s fast food and takeaway market has been expanding rapidly, especially in major cities like Mexico City, Guadalajara, and Monterrey. Customers increasingly prefer eco-friendly packaging, prompting businesses to invest in burger box machines and related equipment. A hamburger box making machine not only improves production efficiency but also ensures consistent quality, meeting both environmental standards and consumer expectations.

YG Machinery’s Solution for Mexican Clients

YG Machinery provides a full range of food packaging machinery solutions. For this client, the solution included:

- Paper Burger Box Machine: Automatic forming and sealing of high-quality burger boxes.

- Paper Cup Machine: To produce matching disposable cups, enhancing the brand’s packaging line.

- Digital Printing Machine: For custom logos and designs, allowing restaurants to brand their packaging.

- Optional accessories and auxiliary equipment for stacking, drying, and packing to streamline the production process.

This integrated solution enables Mexican businesses to efficiently produce custom paper burger boxes while reducing labor costs and meeting strict hygiene and environmental requirements.

FAQs of Hamburger Box Making Machine

During the purchase process, the client focused on several key questions:

1.Production Capacity: How many burger boxes per hour can the machine produce?

YG’s machines offer high-speed production ranging from 1,000 to 5,000 boxes per hour, depending on the model.

2. Material Compatibility: Can it handle eco-friendly kraft paper or coated paper?

Yes, the hamburger box making machine is compatible with various materials, including biodegradable paper, to meet sustainability goals.

3. Maintenance & Support: How easy is it to maintain, and does YG offer after-sales service in Mexico?

YG provides detailed operation manuals, online technical support, and fast spare parts delivery to ensure smooth operation.

4. Integration with Existing Lines: Can it work with other machines like paper cup machines or digital printing machines?

Absolutely. YG designs solutions to integrate multiple food packaging machines, allowing seamless operation across the production line.

Why Choose YG Machinery?

- Proven Quality: Reliable machines with years of successful deployment in international markets.

- Customized Solutions: Tailored configurations for different business scales and local market needs.

- After-Sales Support: Technical guidance, spare parts, and service to minimize downtime.

- Eco-Friendly Focus: Machines compatible with recyclable and biodegradable materials.

With this investment, the Mexican client has successfully upgraded their packaging line, improved efficiency, and enhanced their brand image with eco-friendly packaging.