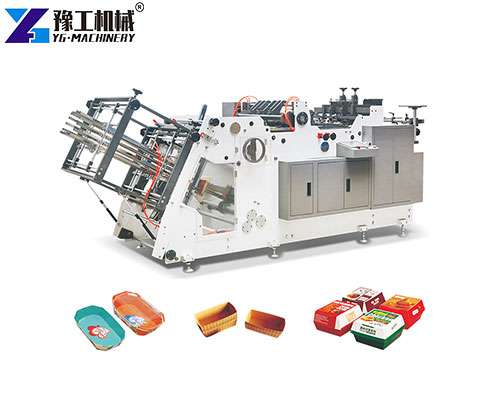

The burger box making machine is designed to produce durable, eco-friendly food boxes used in fast-food restaurants, take-away shops, and packaging factories. With automatic paper feeding, precise molding, and stable heat-pressing technology, the machine delivers consistent box quality and high output. It greatly improves production efficiency compared with manual folding, helping businesses reduce labor costs and meet the growing demand for sustainable food packaging.

burger box making machine Parameters

| Model | YG-800 | YG-C800 | YG-S800 | |

| Paper Cup Size | 3-16OZ | 3-16OZ | 3-16OZ | |

| Raw Material | One-side PE | One-side PE | One-side or two-side PE-coated paper (Singe PE or Double PE coated paper) | |

| Speed | 65-75 pcs/min | 70-80 pcs/min | 75-85 pcs/min | |

| Suitable paper weight | 150-180g;±20g | 150-300g;±20g | 160-300g/;±20g | |

| Voltage supply | 380V, 50HZ | 380V, 50HZ | 380V(220V) 50HZ | |

| cup size | Bottom35-70mm, Top45-90mm High32-135mm | Bottom35-70mm,Top45-90mm, High32-135mm | Bottom35-70mm, Top45-90mm, High32-135mm | |

| General power | 4.5 kW | 5 kW | 6 kW | |

| Working Air Source | NO | NO | 0.4-0.6Mpa; 0.4m3/min | |

| Net weight | 1680kg | 1680kg | 2000kg | |

| Measurement (mm) | L:2115mm;W:1000mm;H:1700mm | L:2115mm;W:1000mm;H:1700mm | Main engine | L:2100mm;W:1200mm;H:1800mm |

| Cup holder | L:900mm;W:600mm;H:1500mm | |||

| Cup Side Sealing | Copper bar heating | Evergreen Ultrasonic | Evergreen Ultrasonic | |

| Bottom Knurling | Heating | Heating | Hot Air System | |

| We can customize the machine and mold according to the customer’s requirements. Also, we have a high-speed machine, 100-120pcs/min. | ||||

Convenience & Benefits in Daily Life

The burger box making machine makes it easier for food companies to offer clean, hygienic, and reliable packaging. Strong heat-pressed folds keep burgers and snacks from leaking, while high-strength kraft paper and coated paper options ensure safe contact with food. This improves both the dining experience and the brand image of restaurants.

Application Scenarios of hamburger box machine

- Fast-food restaurants (burgers, fries, fried chicken)

- Coffee shops and bakeries

- Take-away and delivery packaging

- Food factories and paper packaging plants

- Catering suppliers and wholesalers

To enhance production lines, many customers also purchase compatible equipment such as paper cup machines, paper bowl forming machines, and paper cup printing machines for complete packaging solutions.

UAE Customer Case

A customer from Dubai, UAE, operating a fast-food packaging factory, needed to replace inefficient manual folding stations. After comparing several suppliers, he chose the YG burger box making machine for its stable speed, reinforced structure, and low maintenance.

The machine now produces over 30,000 burger boxes per day, supporting multiple product lines including lunch boxes and clamshell containers. The customer reported smoother operation, fewer paper jams, and a 40% reduction in labor cost—significantly improving overall profitability.

burger box making machine in YG Factory

YG Machinery offers a complete range of food packaging equipment and provides global service support.

- 15+ years of manufacturing experience

- CE-certified machines with stable performance

- Full technical training and online support

- Compatible production lines: paper cup machine, paper bowl machine, digital paper cup printer, flexo printing machine, lunch box forming machine.

With strong R&D capability and strict quality control, YG ensures every client receives reliable machines that perform well in long-term production.