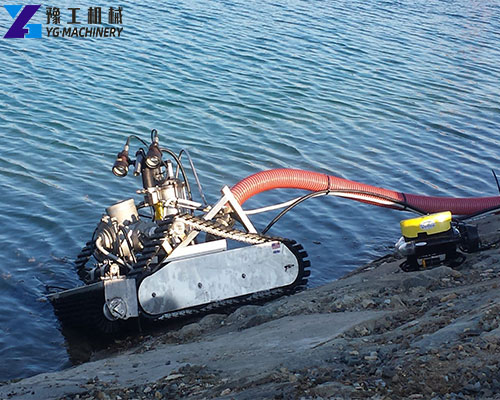

In early 2025, a Nigerian industrial services company purchased a robotic dredge from YG Machinery to clean heavy sludge buildup inside multiple crude-oil storage tanks. Because the working environment involved flammable residues, YG customized the machine with an explosion-proof electric motor, flame-retardant wiring, and a sealed control system. The customer highlighted that the equipment was portable, safe, and highly efficient, and after several weeks of operation, they reported excellent cleaning performance and reduced downtime.

Robotic Dredge Parameters

| Parameter | YG500 | YG600 | YG700 | YG800 | YG900 | YG1200 |

| Robot Dimensions (mm) | 1500*500*650 | 1500*600*650 | 1600*700*650 | 1600*850*700 | 1650*960*750 | 1900*1200*750 |

| Dredging Width (mm) | 500 | 600 | 700 | 800 | 900 | Suitable for large culverts |

| Travel Speed (m/s) | 3–15 | 3–15 | 3–15 | 3–15 | 3–15 | 0–17 m/min |

| Pump Diameter (inch) | 3 | 3 | 4 | 4 | 4 | 4or6 |

| Pump Flow (m³/h) | 100 | 100 | 160 | 160 | 200 | 250 |

| Pump Head (m) | 0–30 | 0–30 | 0–25 | 0–25 | 0–25 | 0–30 (Horizontal: 100–150m) |

| Hydraulic Station Dimensions (mm) | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2120*1240*1200 |

| Main Motor Power (kW) | 18 | 18 | 22 | 22 | 22 | 45KW (50KW) or Diesel 76KW (123KW) |

| Hydraulic System Pressure (Mpa) | 0–16 | 0–16 | 0–16 | 0–16 | 0–16 | Not specified |

| Particle Size (mm) | 15 | 15 | 40 | 40 | 50 | 0–40 (customizable) |

| Winch Speed (r/min) | 0–10 | 0–10 | 0–10 | 0–10 | 0–10 | 0–10 |

| Pipe Length (m) | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30m/pack, 20kg pressure resistant, optional |

| Control System | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote |

| Lighting System | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 |

Why Nigerian Companies Need Robotic Dredging Solutions?

In Nigeria, industries such as refineries, petrochemical plants, lubricant factories, oil depots, and large storage farms face a common challenge:

- Thick sludge accumulates inside oil tanks

- Manual cleaning is hazardous

- Productivity drops when tanks shut down

- Safety regulations are becoming more strict

Many Nigerian clients share the same pain points:

- Workers cannot safely enter confined, flammable spaces

- Traditional dredging pumps block easily

- Cleaning progress is slow and inconsistent

- Environmental compliance requires safer, smarter solutions

These realities make a robotic dredge an ideal substitute for manual cleaning. It eliminates human entry, handles viscous sludge, and works continuously, even in dangerous areas.

YG’s Customized Solution for the Nigerian Project

To match the customer’s requirements, YG delivered a crawler dredging robot designed specifically for oil-tank sludge removal. Key customizations included:

✔ Explosion-Proof Power System

To prevent ignition inside volatile tanks, the robotic dredge was equipped with:

- ATEX-grade explosion-proof motor

- Sealed electrical components

- Anti-static cable set

- High-temperature-resistant materials

✔ Remote-Control Operation for Zero Human Entry

The customer operated the system entirely from outside the tank using a remote control dredging robot system with:

- 200–300m wireless transmission

- Real-time video feed

- Joystick crawler steering

- Pump flow and speed monitoring

This allowed operators to monitor conditions safely, with no need for workers to enter the hazardous confined space.

✔ Underwater & Heavy-Sludge Capability

The unit also functioned as an underwater dredging robot, enabling it to:

- Work beneath oil-water mixtures

- Break and pump high-density sludge

- Handle sediments containing sand and residues

- Maintain stable suction without blockages

With its crawler structure and high-flow pump, the robot delivered efficient, consistent sludge removal across all tank sections.

Customer Feedback After Deployment

After multiple weeks of onsite cleaning, the Nigerian customer shared several positive outcomes:

- Cleaning time reduced by 50% compared with manual or semi-manual methods

- Safety risk dropped to nearly zero, as workers no longer entered the tank

- Pump blockage rate significantly reduced

- Operating cost decreased due to automation and less labor

- Video monitoring improved accuracy, especially for sludge thickness mapping

The customer plans to purchase additional units for refinery pond cleaning and chemical-tank maintenance.

In addition, South African customers have reported very good results using the well dredging robot to clean up lake silt.

FAQ from Nigerian Clients

1) Can the robotic dredge work inside explosive or flammable environments?

Yes. YG provides explosion-proof electric motors, sealed wiring, and anti-static systems specifically for oil, chemical, and fuel storage applications.

2) Can the crawler dredging robot clean thick crude-oil sludge?

Absolutely. The crawler tracks maintain high traction, while the pump handles dense sludge, sand-oil mixtures, and long-settled deposits.

3) How far can the remote control dredging robot operate?

Standard operation range is 200–300 meters, with both wireless and wire-control backup options.

4) Is camera visibility possible inside dark tanks?

Yes. YG robots come with LED floodlights + HD visual monitoring, allowing operators to see sediment locations clearly.

5) Can it be used in water bodies outside factories?

Yes. Many clients also deploy it as an underwater dredging robot for ponds, reservoirs, sewage tanks, and lagoons.

6) What maintenance does the robot require?

- Clean pump and pipes after each shift

- Check crawler tension weekly

- Replace seals regularly in oil-based environments

- Perform remote-control signal testing monthly

Why Nigerian Companies Choose YG Machinery?

- 10+ years of sludge-cleaning equipment manufacturing

- Customized explosion-proof options for oil and chemical industries

- Rich experience in tank cleaning, lagoon dredging, and refinery sludge removal

- Fast delivery to West Africa

- 24/7 technical support + remote training

YG Machinery provides reliable robotic dredging solutions that match Nigeria’s industrial reality—reducing risk, increasing efficiency, and ensuring compliance with safety regulations.