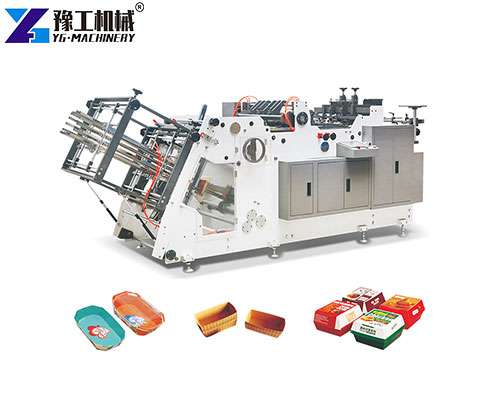

A Rwandan client recently expanded their food packaging production line by purchasing a paper box forming machine from YG Machinery. The new equipment allowed them to efficiently produce a variety of paper food containers, including burger boxes and lunch boxes, while maintaining high-quality standards. After integrating the machine, the client reported significant improvements in production efficiency and product consistency.

Growing Demand for Paper Box Forming Machines in Rwanda

Rwanda’s food packaging industry is rapidly developing due to the growth of fast food restaurants, catering services, and takeaway businesses in urban areas such as Kigali. Local companies increasingly prefer eco-friendly and high-quality paper packaging, creating a rising demand for paper box forming machines.

The need for automated solutions, including burger box machines and lunch box forming machines, is essential for businesses aiming to scale production while reducing labor costs and improving hygiene standards.

YG Machinery’s Solution for Rwandan Clients

YG Machinery offers tailored solutions for fast food and food packaging production lines. For this Rwandan client, the solution included:

- Paper Box Forming Machine: Efficient automatic forming and sealing of various paper food boxes.

- Burger Box Machine & Lunch Box Forming Machine: For producing specific types of takeaway containers.

- Paper Cup Machine: To expand their beverage packaging options.

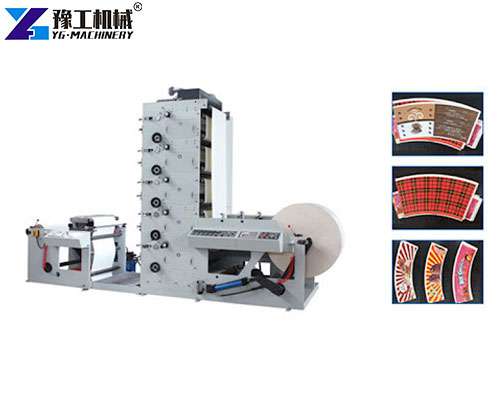

- Digital Printing Machine: Enables branding and customized designs on boxes and cups.

- Auxiliary equipment such as stacking, drying, and packing systems to ensure smooth production.

This complete solution allows Rwandan clients to efficiently operate a modern food packaging line, producing eco-friendly disposable containers with minimal labor.

Investment ROI and Benefits

Investing in a paper box forming machine can bring efficient production and meaningful cost savings for Rwandan food packaging businesses:

- High Production Efficiency: Produce hundreds to thousands of boxes per hour, depending on production scale, operational factors, and raw material availability.

- Labor Savings: One to two operators can manage the machine efficiently, reducing manpower costs while maintaining high output.

- Material Flexibility: Compatible with biodegradable paper and coated paper, supporting eco-friendly packaging initiatives.

- Integration: Can work seamlessly with burger box machines, lunch box forming machines, paper cup machines, and digital printing machines, enabling a flexible and scalable production line.

Many clients in Rwanda report achieving ROI within 6–8 months, depending on production volume, sales channels, and market demand. This realistic timeline reflects local operational conditions while demonstrating the strong potential for growth and profitability.

Client FAQs of paper box forming machine

1.How many boxes can the machine produce per hour?

YG’s paper box forming machines can produce 1,000–5,000 boxes per hour depending on the model.

2.Can it handle eco-friendly materials?

Yes, the machine supports various materials including biodegradable paper and food-grade coated paper.

3.Is after-sales support available in Rwanda?

YG provides online technical support, spare parts delivery, and manuals to ensure smooth operation.

4.Can it integrate with other machines in the production line?

Absolutely. YG’s solution allows seamless integration with burger box machines, lunch box forming machines, paper cup machines, and digital printing machines.

5.Is it suitable for small and medium-sized enterprises?

Yes, the machine is user-friendly and ideal for businesses expanding their production lines.

Why Choose YG Machinery?

- Proven international quality and reliability.

- Customized solutions for different business scales.

- Eco-friendly and sustainable production options.

- Comprehensive technical and after-sales support.

With the addition of YG’s paper box forming machine, this Rwandan client successfully expanded their food packaging production line, producing high-quality paper containers efficiently while meeting growing local demand.