An HDPE garbage bin production line was recently delivered and commissioned in Vietnam to support the growing demand for residential waste bins driven by rapid urbanization and waste classification initiatives.

As Vietnamese cities continue to expand, local municipalities and property developers are placing increasing emphasis on standardized waste collection systems. This has created a strong market for 120L and 240L HDPE garbage bins, especially for residential communities, apartment complexes, and suburban housing projects.

Background: Why Vietnam Is a Strong Market for HDPE Garbage Bin Production

Vietnam is one of the fastest-urbanizing countries in Southeast Asia. With new residential areas emerging every year, local governments are actively promoting basic waste sorting and standardized bin usage at the community level.

However, the local market is dominated by small to medium plastic product manufacturers, many of which lack integrated production lines for large-volume waste bins. Importing finished bins is costly and slow, while low-end equipment often fails to meet durability and output requirements.

This gap makes Vietnam an ideal market for a medium-capacity HDPE garbage bin production line—a solution that balances investment cost, production efficiency, and fast return on investment.

Client Profile and Project Requirements

The Vietnamese client is a regional plastic products manufacturer with experience in household plastic items. The company aimed to expand into municipal and residential waste bins with the following requirements:

- Focus on 120L and 240L HDPE garbage bins

- Stable daily output suitable for local distribution

- Moderate initial investment with short ROI cycle

- Easy operation and maintenance for local technicians

- Finished bins suitable for outdoor use in tropical climates

After evaluating several options, the client selected a customized HDPE garbage bin production line designed specifically for Southeast Asian operating conditions.

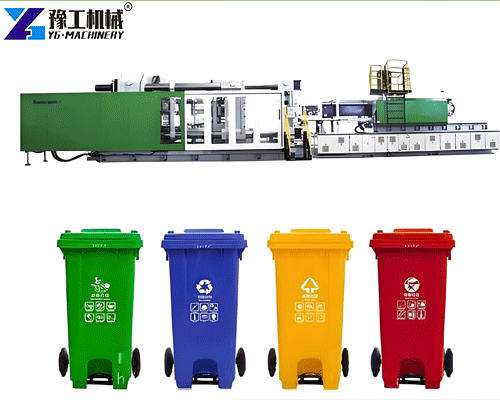

Solution: Customized HDPE Garbage Bin Production Line

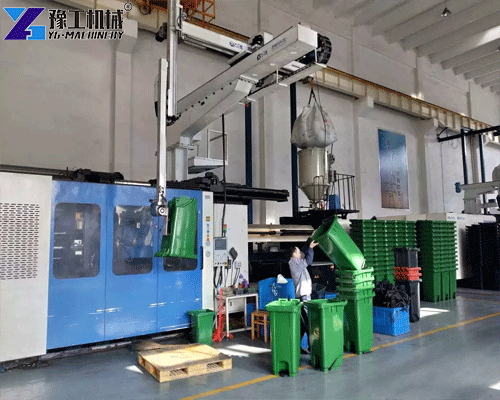

YG Machinery provided a complete HDPE garbage bin production line, including molding system, material handling, cooling, and trimming processes. The line was optimized for continuous production of 120L and 240L residential bins, which represent the highest-demand sizes in Vietnam.

Key configuration features included:

- High-efficiency molding system for HDPE materials

- Stable cycle time to ensure consistent daily output

- Reinforced mold structure for long service life

- Energy-efficient operation suitable for local power conditions

The entire line was designed for medium-scale production, allowing the client to enter the market quickly without excessive capital pressure.

| Number | Capacity(L) | Size(MM) | Weight(KG) | Roller(KG) | Barrel(KG) | Lid(KG) | Total Weight(KG) |

| 1 | 100 | 480*530*790 | 2.6 | 1.2 | 4.55 | 0.71 | 9.06 |

| 2 | 120 | 530*475*925 | 2.6 | 1.2 | 5.7 | 0.73 | 10.23 |

| 3 | 240 | 725*585*1020 | 2.6 | 1.5 | 9.34 | 1.62 | 15.06 |

| 4 | 240 | 735*590*1070 | 2.6 | 1.5 | 9.5 | 1.53 | 15.13 |

| 5 | 360 | 705*845*1110 | 2.6 | 1.8 | 15.8 | 2 | 22.2 |

Adapted for Vietnam’s Climate and Usage Conditions

Vietnam’s hot, humid climate places higher demands on plastic waste bins, especially those used outdoors. The HDPE garbage bin production line was configured to support:

- UV-resistant HDPE formulations

- Thickened stress points on handles and wheels

- Smooth surface finish for easy cleaning

- Structural strength suitable for frequent residential use

These features ensure that the produced bins maintain shape, strength, and appearance even under long-term outdoor exposure.

Production Results and Market Response

After installation and commissioning, the HDPE garbage bin production line achieved stable operation within a short time. The client reported:

- Consistent production of 120L and 240L bins

- Low material waste and stable quality

- Reduced dependence on imported finished bins

- Faster delivery to local distributors and contractors

The bins were quickly adopted in residential projects, gated communities, and local sanitation contracts, helping the client secure repeat orders and expand regional distribution.

Investment Value and ROI Outlook

Compared with large-scale municipal projects in the Middle East, the Vietnamese market favors faster turnover and flexible production. This production line offers:

- Medium investment level suitable for local manufacturers

- High-demand product sizes with quick sales cycles

- Lower logistics and storage costs

- Scalable expansion potential as demand grows

For manufacturers targeting residential waste management in Vietnam, this type of production line provides a clear and practical growth path.

Why Choose YG’s hdpe wheelie bin production line?

YG Machinery is a professional Chinese manufacturer specializing in plastic bin production solutions. With over 20 years of export experience, YG has supplied equipment to customers across Southeast Asia, the Middle East, Latin America, and Africa.

By understanding local market needs and adapting equipment configurations accordingly, YG helps manufacturers build reliable production capacity and achieve long-term success.

Conclusion

This Vietnam project demonstrates how a well-configured HDPE garbage bin production line can meet local market demand while maintaining a balanced investment profile. For manufacturers seeking to enter or expand in Vietnam’s residential waste bin market, this solution offers stability, efficiency, and strong commercial potential.