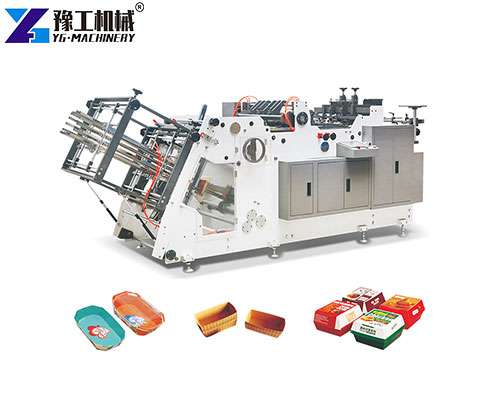

As the global fast-food industry continues to grow, the demand for eco-friendly and high-quality food packaging has increased dramatically. Many packaging factories are now upgrading from manual production to fully automated equipment. A Burger Box Machine—Hamburger Box Making Machine—has become an essential piece of equipment for manufacturers who want to boost production capacity, reduce labor costs, and meet the rising standards of international markets.

Whether you produce hamburger boxes, lunch boxes, take-out packaging, or paper trays, a Burger Box Machine enables you to achieve stable, high-speed, and clean processing for food-grade packaging.

Burger Box Machine Parameters

| Model | YG-800 | YG-C800 | YG-S800 | |

| Paper Cup Size | 3-16OZ | 3-16OZ | 3-16OZ | |

| Raw Material | One-side PE | One-side PE | One-side or two-side PE-coated paper (Singe PE or Double PE coated paper) | |

| Speed | 65-75 pcs/min | 70-80 pcs/min | 75-85 pcs/min | |

| Suitable paper weight | 150-180g;±20g | 150-300g;±20g | 160-300g/;±20g | |

| Voltage supply | 380V, 50HZ | 380V, 50HZ | 380V(220V) 50HZ | |

| cup size | Bottom35-70mm, Top45-90mm High32-135mm | Bottom35-70mm,Top45-90mm, High32-135mm | Bottom35-70mm, Top45-90mm, High32-135mm | |

| General power | 4.5 kW | 5 kW | 6 kW | |

| Working Air Source | NO | NO | 0.4-0.6Mpa; 0.4m3/min | |

| Net weight | 1680kg | 1680kg | 2000kg | |

| Measurement (mm) | L:2115mm;W:1000mm;H:1700mm | L:2115mm;W:1000mm;H:1700mm | Main engine | L:2100mm;W:1200mm;H:1800mm |

| Cup holder | L:900mm;W:600mm;H:1500mm | |||

| Cup Side Sealing | Copper bar heating | Evergreen Ultrasonic | Evergreen Ultrasonic | |

| Bottom Knurling | Heating | Heating | Hot Air System | |

| We can customize the machine and mold according to the customer’s requirements. Also, we have a high-speed machine, 100-120pcs/min. | ||||

What Is a Burger Box Machine?

A Burger Box Machine is a specialized piece of paper box forming equipment used to produce:

- Hamburger boxes

- Fast-food clamshell containers

- French fry boxes

- Snack boxes

- Paper lunch boxes

- Chicken popcorn boxes

Using heated molding, auto folding, and precise edge pressing, the machine delivers perfectly shaped packaging that meets the hygiene and durability requirements of fast-food chains.

For factories that already use paper cup machine or other paper-forming machinery, adding a Burger Box Machine is a highly compatible upgrade—sharing similar materials, production environments, and packaging needs.

Key Features & Advantages of YG Burger Box Machine

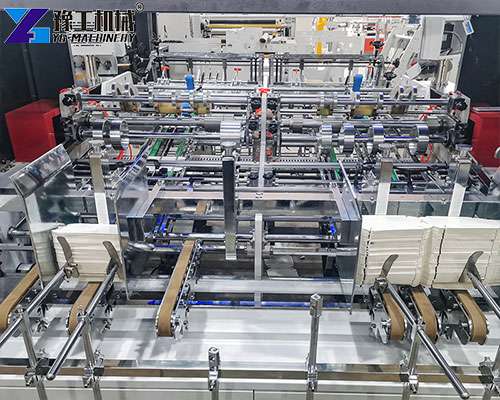

- High-Speed Production (Up to 150–300 pcs/min)

Compared with manual folding or semi-automatic equipment, fully automatic burger box forming machines greatly increase output while keeping transitions smooth and consistent.

- Multi-Mold Compatibility

One machine can form:

- hamburger box

- lunch box

- cake box

- food clamshell

- customized folding cartons

Mold change is simple and typically takes only 30–40 minutes.

- Eco-Friendly Material Support

The Burger Box Machine supports:

- coated paper

- kraft paper

- white cardboard

- biodegradable food-grade materials

This helps factories comply with US and EU environmental policies.

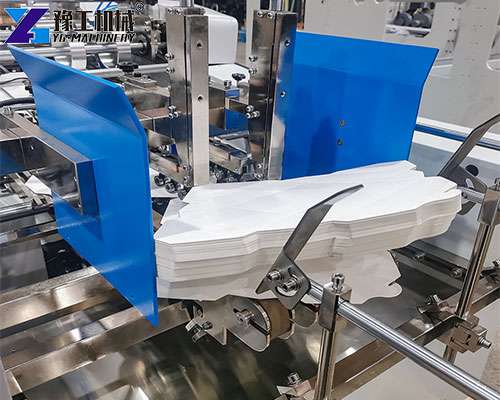

- Automatic System for Lower Labor Costs

The machine combines:

- Automatic paper feeding

- Heating

- Creasing

- Folding

- Forming

- Counting & collecting

One operator can manage the entire production line, greatly reducing labor input.

- Stable Performance & Low Failure Rate

YG’s patented forming system ensures:

- precise box shaping

- strong creases

- tight folding edges

- minimal glue usage

- long-term stable operation

The entire structure is made with reinforced frames and high-quality electrical components for long service life.

Common Applications of hamburger Box Machine

The Burger Box Machine is suitable for:

- Fast-food packaging factories

- Paper packaging manufacturing plants

- Take-out meal box suppliers

- Quick service restaurant (QSR) supply chains

- New startup factories upgrading from manual folding

- Factories already running paper cup machines who want to expand packaging products

This machine is widely used in industries supplying packaging for burgers, fried chicken, pastries, snacks, desserts, and various hot foods.

Investment Benefits: Why It Is Worth Buying?

- Fast Return on Investment (ROI)

Because of the high production speed and low labor requirements, most customers recover their investment within 3–6 months.

- Increase Monthly Output by 300%–500%

Compared with manual or semi-automatic forming processes, automatic equipment dramatically boosts production, enabling factories to accept larger and higher-value orders.

- Expand Product Line Without Extra Labor

If a factory already owns paper cup machines, printing machines, or die-cutting machines, the Burger Box Machine expands the business without needing to hire additional staff.

- Strong Market Demand

With global food delivery and QSR expansion, hamburger boxes and lunch boxes maintain high consumption levels year-round.

Case Study: YG Burger Box Machine Sold to the United States

A US fast-food packaging supplier from Texas contacted YG with a clear goal:

increase daily hamburger box output while reducing dependence on manual labor.

Their previous process required 6 workers folding boxes manually, producing only 20,000 pcs/day.

After installing a YG automatic Burger Box Machine, the results were:

- Daily output increased to 80,000 pcs/day

- Labor reduced from 6 workers to 1 operator

- Box quality became more consistent, meeting standards for several fast-food chains

- The customer recovered investment in 4 months

The buyer later purchased additional equipment including a paper cup forming machine and a flexo printing machine to complete a full fast-food packaging line.

Why Choose YG Machinery?

- 15+ years of food packaging machinery R&D

- Strong factory manufacturing capability

- Machines exported to 20+ countries

- Fast delivery, stable components, and 24/7 after-sales service

- Can provide complete packaging lines including:

- burger box machine

- paper cup machine

- flexo printing machine

- die cutting machine

- paper bowl machine

YG is not only a machine provider but a long-term partner for packaging factories.

Conclusion

A Burger Box Machine is a reliable, high-return investment for any packaging manufacturer seeking higher productivity, lower labor cost, and stable output quality. With growing global demand for eco-friendly fast-food packaging, now is the ideal time to upgrade your production line.

If you need machine videos, technical specifications, or a free quotation, YG Machinery can provide a complete solution tailored to your business.【WhatsApp/WeChat/Phone】+86 13837115193.