With India’s rapid industrialization, the demand for sludge removal equipment in petrochemical plants, chemical plants, and municipal wastewater treatment plants is rising rapidly. Many plants still rely on manual entry into oil tanks or sedimentation ponds for sludge removal, which is not only inefficient but also poses serious safety hazards. Seeking a more automated and safer solution, a petrochemical company from Gujarat, India, contacted YG in April 2025, hoping to purchase an automatic sludge removal robot to clean the heavy oil sludge deposited at the bottom of large oil tanks.

Automatic Sludge Removal Robot Parameters

| Parameter | YG500 | YG600 | YG700 | YG800 | YG900 | YG1200 |

| Robot Dimensions (mm) | 1500*500*650 | 1500*600*650 | 1600*700*650 | 1600*850*700 | 1650*960*750 | 1900*1200*750 |

| Dredging Width (mm) | 500 | 600 | 700 | 800 | 900 | Suitable for large culverts |

| Travel Speed (m/s) | 3–15 | 3–15 | 3–15 | 3–15 | 3–15 | 0–17 m/min |

| Pump Diameter (inch) | 3 | 3 | 4 | 4 | 4 | 4or6 |

| Pump Flow (m³/h) | 100 | 100 | 160 | 160 | 200 | 250 |

| Pump Head (m) | 0–30 | 0–30 | 0–25 | 0–25 | 0–25 | 0–30 (Horizontal: 100–150m) |

| Hydraulic Station Dimensions (mm) | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2120*1240*1200 |

| Main Motor Power (kW) | 18 | 18 | 22 | 22 | 22 | 45KW (50KW) or Diesel 76KW (123KW) |

| Hydraulic System Pressure (Mpa) | 0–16 | 0–16 | 0–16 | 0–16 | 0–16 | Not specified |

| Particle Size (mm) | 15 | 15 | 40 | 40 | 50 | 0–40 (customizable) |

| Winch Speed (r/min) | 0–10 | 0–10 | 0–10 | 0–10 | 0–10 | 0–10 |

| Pipe Length (m) | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30m/pack, 20kg pressure resistant, optional |

| Control System | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote |

| Lighting System | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 |

Indian Customer Background & Pain Points

The Indian customer manages multiple crude oil storage tanks and faces the following challenges:

- High risk of manual entry into tanks: High oil and gas concentrations and confined environments pose a risk of asphyxiation or explosions in the event of a leak.

- High viscosity and deep deposition of oil sludge: Ordinary dredging robots cannot handle high-viscosity sludge.

- Requirement for explosion-proof equipment: Indian petrochemical plants have very strict requirements for explosion-proof standards (ATEX/IECEx equivalent).

- Short cleaning cycles, high downtime losses: Lower cleaning efficiency leads to higher downtime costs for refineries.

YG’s Tailored Solution for the Indian Market

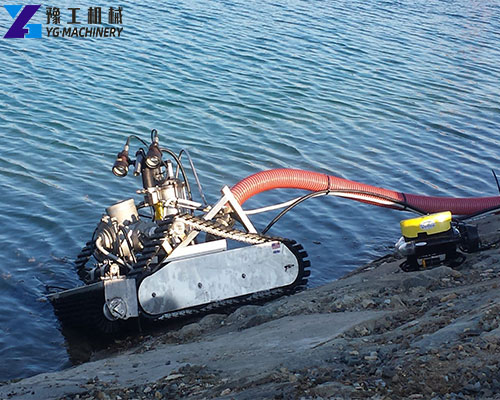

Based on customer needs, YG provided an automatic sludge removal robot solution, combining the strong traction of a crawler dredging robot with the high suction power of a sludge cleaning robot, while also incorporating an explosion-proof motor system specifically requested by the Indian customer.

YG’s core configuration includes:

- Ex-proof explosion-proof motor (suitable for use inside oil and chemical tanks)

- High negative pressure sludge suction pump, enhancing the ability to pump out thick sludge

- Crawler structure design, allowing stable movement in heavy sludge

- Remote remote control system, eliminating the need for personnel to enter the tank

- Underwater dredging robot configuration, enabling operation in wet environments

- Camera + lighting system, supporting real-time monitoring

- Automatic filtration and recirculation system (optional)

Following technical evaluation, we recommended the following to our client:

➡ YG–R550 Automatic Sludge Removal Robot (Explosion-proof version)

This model is suitable for high-risk environments such as large petrochemical oil tanks, sedimentation tanks, and refinery sludge ponds.

The client was particularly satisfied with the explosion-proof motor and crawler system, as downtime costs at the Indian plant are high, and these two features significantly improved safety and operational efficiency.

Project Implementation & Results

After the equipment was shipped to India, YG engineers provided remote installation guidance.

Application Scenarios:

- Petrochemical plant crude oil storage tanks (50,000–150,000 m³)

- Sludge removal from the bottom of condensate tanks

- Sludge cleaning in chemical sedimentation tanks

- Sediment dredging in industrial wastewater treatment plants

Customer Feedback:

- Dredging efficiency increased by more than 3 times

- Complete unmanned operation within the tanks in one week

- Meets local explosion-proof standards, easily passing safety inspections

The customer subsequently ordered a second sludge cleaning robot for their wastewater treatment plant.

And the sludge cleaning robot is widely welcomed in South Africa and Nigeria, bringing continuous factory visits and purchases.

FAQ – Indian Customers’ Most Common Questions

- Can the automatic sludge removal robot clean thick and sticky crude oil?

Yes. The robot is designed for high-viscosity sludge. With a high negative pressure pump and crawler drive, it can easily remove heavy crude oil sediment.

- Do you provide an explosion-proof motor?

Yes. YG can equip ATEX / IECEx equivalent explosion-proof motors, suitable for oil tanks, chemical tanks, and hazardous areas.

- How deep can the underwater dredging robot work?

Typically up to 8–12 meters underwater, depending on working conditions.

- What is the delivery time to India?

Usually 15–25 days, depending on customization (especially EX motor requirements).

- Can one robot clean multiple tanks?

Yes. One machine can serve multiple tanks. Many Indian clients rotate the robot among different refinery areas.

- What maintenance is required?

Just replace seals, clean the pump, and check the cable system. We provide full maintenance manuals.

Why Indian Clients Choose YG Machinery?

- ✔ Extensive overseas oil-tank cleaning experience: Provided sludge robot equipment to numerous petrochemical companies in the Middle East, Africa, and South Asia.

- ✔ Customizable explosion-proof systems: Supports multiple standards including ATEX, IECEx, Ex d, and Ex e.

- ✔ Robust crawler dredging robot: Suitable for high-viscosity oily sludge, sedimentation tanks with water, and chemical sludge.

- ✔ Remote service support: Video installation guidance, hands-on training, and rapid response throughout the entire troubleshooting process.