A plastic wheelie bin making machine was successfully supplied to a waste management equipment manufacturer in Qatar, mainly for the production of large-capacity HDPE wheelie bins used in municipal sanitation and public infrastructure projects. The solution was engineered to meet Qatar’s hot climate conditions and long-term outdoor application requirements.

Project Background: Growing Demand for Wheelie Bins in Qatar

With continuous urban expansion and large-scale infrastructure development, Qatar has increased investment in municipal waste management systems. Standardized plastic wheelie bins are now widely required for:

- Urban residential areas

- Commercial zones and public facilities

- Stadiums, parks, and transportation hubs

- Government sanitation outsourcing projects

The client is a local plastic products manufacturer aiming to strengthen its position in the Qatar municipal wheelie bin supply chain by establishing stable, in-house bin production capacity.

Customer Challenges Before the Investment

Before selecting the equipment, the client faced several production limitations:

- Outsourced wheelie bin supply caused long delivery cycles

- Inconsistent bin quality affected municipal acceptance

- Existing molding equipment lacked stability for large bins

- High rejection rates under high-temperature working conditions

To solve these issues, the client required a plastic wheelie bin making machine for Qatar that could ensure consistent output, strong structural performance, and long service life.

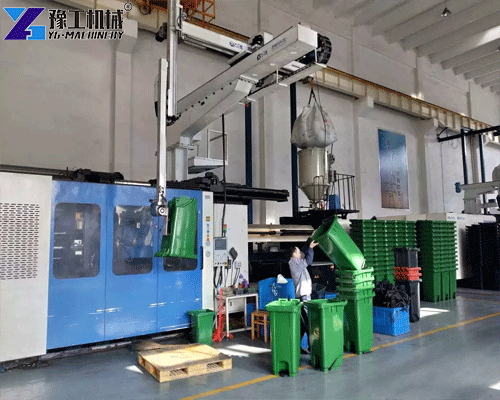

Machine Solution: Optimized Plastic Wheelie Bin Manufacturing Line

Based on the client’s production goals, we supplied a plastic wheelie bin making machine configured specifically for municipal-grade bin production.

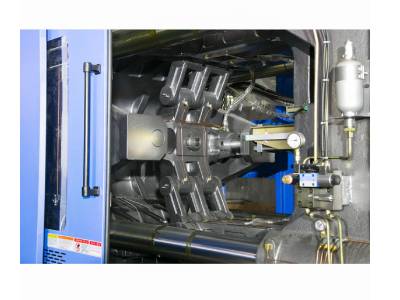

Key Configuration Highlights

- HDPE material compatibility for durable outdoor wheelie bins

- Stable molding system ensuring uniform wall thickness

- Reinforced structure for bin body, axle, and wheel mounting areas

- Designed for continuous operation under high ambient temperatures

This setup allows the factory to efficiently produce HDPE wheelie bins for municipal waste management, meeting local tender and contractor requirements.

| Number | Capacity(L) | Size(MM) | Weight(KG) | Roller(KG) | Barrel(KG) | Lid(KG) | Total Weight(KG) |

| 1 | 100 | 480*530*790 | 2.6 | 1.2 | 4.55 | 0.71 | 9.06 |

| 2 | 120 | 530*475*925 | 2.6 | 1.2 | 5.7 | 0.73 | 10.23 |

| 3 | 240 | 725*585*1020 | 2.6 | 1.5 | 9.34 | 1.62 | 15.06 |

| 4 | 240 | 735*590*1070 | 2.6 | 1.5 | 9.5 | 1.53 | 15.13 |

| 5 | 360 | 705*845*1110 | 2.6 | 1.8 | 15.8 | 2 | 22.2 |

| 6 | 660 | 1285*775*1295 | 12 | 26.15 | 6.6 | 44.75 | |

| 7 | 1100 | 1060*1200*1295 | 12 | 29.4 | 6.85 | 48.25 |

Why Plastic Wheelie Bins Are Widely Used in Qatar?

Plastic wheelie bins are preferred in Qatar due to their practicality and durability in public environments. Compared with metal or smaller household bins, they offer:

- High capacity for centralized waste collection

- Resistance to corrosion and moisture

- Compatibility with standard waste collection vehicles

- Lower maintenance costs for municipal operators

Using a plastic wheelie bin manufacturing machine enables local producers to respond quickly to project-based demand and reduce reliance on imported finished bins.

Production Results After Installation

After commissioning the machine, the client reported clear improvements:

- Stable daily production output of plastic wheelie bins

- Improved consistency in bin size and structure

- Reduced defect rate and material waste

- Faster response to municipal and contractor orders

The plastic wheelie bin making machine has since become a core production asset, supporting both ongoing municipal supply and future capacity expansion.

Why This Solution Fits the Qatar Market?

Qatar’s climate and project-based procurement model require equipment that emphasizes reliability, durability, and production stability. This solution focuses on:

- Long-term performance in high-temperature outdoor environments

- Consistent quality for municipal acceptance

- Scalable production for government and infrastructure projects

For manufacturers targeting the Middle East market, investing in a plastic wheelie bin making machine in Qatar provides a practical pathway to sustainable growth.

HDPE garbage bin manufacturing machine in Middle East

This Qatar case demonstrates how a properly configured plastic wheelie bin making machine can help local manufacturers establish reliable wheelie bin production for municipal waste management. By aligning equipment capability with real application needs, the client successfully improved production efficiency and market competitiveness.

garbage trash bin making machine in YG Machinery

YG is a leading Chinese manufacturer of plastic garbage bin and wheelie bin production equipment, with over 20 years of export experience serving customers in Saudi Arabia, Qatar, and other Middle East markets. YG machines are widely used for producing municipal-grade plastic garbage bins designed for high-temperature, high-UV, and outdoor operating environments common across the region.

With extensive project experience in Middle East municipal waste management, YG provides reliable solutions for HDPE wheelie bin production, focusing on long-term stability, consistent quality, and compliance with local project requirements. Continuous cooperation with regional distributors and municipal contractors reflects YG’s strong reputation and trust in the Middle East market.