With the rapid growth of the beverage takeaway, coffee shop chains, and fast-food markets in the United States, the demand for branded paper cups has become mainstream. Many American customers want to print their brand logos on paper cups while using environmentally friendly materials (such as biodegradable paper cups or PLA-coated paper cups) to comply with local policies and sustainability requirements. This article shares how an American customer improved paper cup printing quality, stabilized production efficiency, and successfully integrated YG’s paper cup logo printing machine with their existing paper cup forming machine to achieve an efficient and environmentally friendly paper cup production line.

Paper Cup Logo Printing Machine Parameters

| Model | Printing Width | Printing Length | Printing Speed | Plate Thickness | Machine Dimension |

| DX-2600 | 600mm | 180-1200mm | 60m/min | 2.38m | 2.3*1.6*2.2m |

| DX-2800 | 800mm | 180-1200mm | 60m/min | 2.38m | 2.3*1.8*2.2m |

| DX-21000 | 1000mm | 180-1200mm | 60m/min | 2.38m | 2.3*2.0*2.2m |

| DX-4600 | 600mm | 180-1200mm | 60m/min | 2.38m | 4.8*1.6*2.4m |

| DX-4800 | 800mm | 180-1200mm | 60m/min | 2.38m | 4.8*1.8*2.4m |

| DX-41000 | 1000mm | 180-1200mm | 60m/min | 2.38m | 4.8*2.0*2.4m |

| DX-6600 | 600mm | 180-990mm | 60m/min | 2.38m | 4.8*2.0*2.4m |

| DX-6800 | 800mm | 180-990mm | 60m/min | 2.38m | 4.8*1.8*2.8m |

| DX-61000 | 1000mm | 180-990mm | 60m/min | 2.38m | 4.8*2.0*2.8m |

Current Needs of American Customers

American customers generally face the following problems:

- Strong demand for branding and customization

- Large coffee chains and restaurant brands require clear, color-stable logos printed on their paper cups.

- The increase in small-batch, multi-variety orders makes it difficult for traditional printing machines to respond quickly.

- Environmental policy restrictions

- Local policies encourage biodegradable paper cups and PLA-coated paper cups to reduce plastic use.

- Customers want printing equipment that is compatible with environmentally friendly materials without compromising molding quality.

- High requirements for matching with paper cup machines

- Paper cup forming machines have high production rates, and old printing equipment can easily create production line bottlenecks.

- Pattern misalignment and unstable ink color can affect cup formation and customer experience.

The customer summarized:

“In the US market, paper cups must not only be aesthetically pleasing and branded, but also meet environmental requirements, which is a test for both printing and forming equipment.”

⭐ YG’s Solution for paper cup logo printing machine

To address the needs of American customers, YG provided a complete paper cup logo printing machine + paper cup forming machine solution.

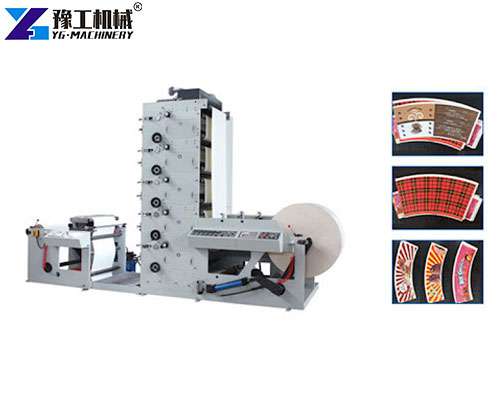

✔ 1. High-Precision Flexible Paper Cup Printing Machine (Flexographic Printing Machine)

- High-precision registration system: Ensures accurate printing of logos and patterns

- Supports various environmentally friendly materials: Biodegradable paper cups, PLA-coated paper cups

- Stable color: Maintains consistency even at high production speeds

- Perfectly matched with paper cup machines: Synchronized speed to avoid production line downtime

✔ 2. Optimized Production Line with Matching Paper Cup Machines

- Speed matching between the printing machine and paper cup machine

- Ensures smooth and crack-free molding of environmentally friendly paper cup materials

- Automated entire line reduces manual intervention and improves production efficiency

✔ 3. Sample Testing and Color Management Services

- Provides ink and print sample testing

- Optimizes printing thickness and color saturation

- Ensures consistent logo appearance on different paper cup materials

✔ 4. After-Sales Support and Training

- Remote installation guidance in the US

- Fast spare parts supply

- 24-hour technical support

- Training of operators to ensure smooth production

⭐ Customer Feedback of Flexographic Printing Machine

US customers reported after use:

- Significant improvement in print quality, clear logos and vibrant colors

- Production efficiency increased by 2–3 times

- Good compatibility with environmentally friendly paper cups, complying with local regulations

- Excellent overall line coordination, perfect match between the paper cup machine and printing machine

Customer summary:

“Using YG’s paper cup logo printing machine, we not only enhanced our brand value but also met environmental regulations, resulting in a significant increase in orders.”

⭐FAQ from US Customers

- Can biodegradable paper cups be printed stably?

Yes. YG’s flexible paper cup printing machine is specifically designed for environmentally friendly paper cup materials and is compatible with PLA, PE coating, and biodegradable paper cups.

- How many colors can one printing machine support?

2–8 color printing options are available to meet the multi-color logo needs of brands.

- Can the printing machine be integrated with existing paper cup machines?

Absolutely. YG can customize the entire line matching solution based on the customer’s paper cup machine speed and size.

- How to handle small batch, diversified orders?

It can be combined with a flexible printing machine or digital printing machine to achieve fast switching and high-precision printing.

- What is the return on investment period?

Depending on the output, the investment can generally be recovered in 6–12 months, while also improving environmental compliance and brand value.

⭐Enhance the Competitiveness of Paper Cup Production in the US

In the US market, paper cup production needs to be not only efficient but also aesthetically pleasing, branded, and environmentally friendly. A high-precision paper cup logo printing machine is crucial for improving the efficiency of the paper cup production line, ensuring high-quality logo printing, and compatibility with environmentally friendly materials.

YG Machinery provides complete line solutions, from printing machines to paper cup machines, ensuring stable and efficient operation of the production line. This allows customers to achieve a higher ROI in the US market, comply with environmental regulations, and enhance their brand competitiveness.