With the rapid growth of the beverage takeaway market, catering industry, and coffee shop chains in Mexico, the demand for disposable paper cups is constantly increasing. However, many Mexican paper cup factories still rely on traditional printing equipment, resulting in slow printing speeds, inconsistent colors, and high labor costs, making it difficult to meet the market’s demand for high-quality custom paper cups.

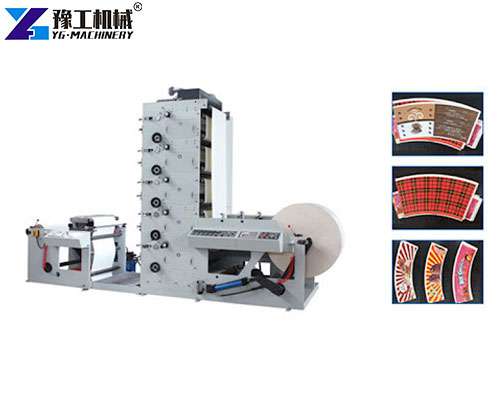

This case study shares how a client from Mexico successfully improved paper cup printing quality, reduced production costs, and achieved efficient collaboration across their entire production line (including paper cup machines) by purchasing a YG paper cup printing machine, providing a valuable solution for local factory owners.

Paper Cup Printing Machine Parameters

| Model | Printing Width | Printing Length | Printing Speed | Plate Thickness | Machine Dimension |

| DX-2600 | 600mm | 180-1200mm | 60m/min | 2.38m | 2.3*1.6*2.2m |

| DX-2800 | 800mm | 180-1200mm | 60m/min | 2.38m | 2.3*1.8*2.2m |

| DX-21000 | 1000mm | 180-1200mm | 60m/min | 2.38m | 2.3*2.0*2.2m |

| DX-4600 | 600mm | 180-1200mm | 60m/min | 2.38m | 4.8*1.6*2.4m |

| DX-4800 | 800mm | 180-1200mm | 60m/min | 2.38m | 4.8*1.8*2.4m |

| DX-41000 | 1000mm | 180-1200mm | 60m/min | 2.38m | 4.8*2.0*2.4m |

| DX-6600 | 600mm | 180-990mm | 60m/min | 2.38m | 4.8*2.0*2.4m |

| DX-6800 | 800mm | 180-990mm | 60m/min | 2.38m | 4.8*1.8*2.8m |

| DX-61000 | 1000mm | 180-990mm | 60m/min | 2.38m | 4.8*2.0*2.8m |

Current Situation of the Mexican Client

During the consultation, the Mexican client stated that his factory faced similar problems to many other paper cup manufacturers in the region:

1) Outdated Traditional Printing Methods

Many Mexican factories still use old printing presses or low-end digital printing machines, resulting in:

- Blurred patterns and noticeable color differences

- Ink penetration and poor adhesion

- Inability to meet the customization requirements of chain coffee shops

2) Printing Speed Cannot Keep Up with Paper Cup Machine Output

Paper cup forming machines can produce 60-120 cups per minute, but old printing presses can only manage 30-40 cups, creating a production bottleneck.

3) Difficult Maintenance and High Downtime Rate

The supply chain for mechanical parts in the Mexican market is weak, leading to slow repairs after breakdowns and affecting order delivery.

4) Increased Customer Brand Awareness Requires Higher Printing Quality

Restaurant chains and large beverage brands want paper cups to display brighter colors, high-definition logos, and a consistent visual effect.

A quote from the client left a strong impression on us:

“In Mexico, it’s no longer about who can make paper cups, but who can make good-looking, high-quality paper cups with a stable supply.”

This is also the common sentiment of many Mexican paper cup manufacturers.

YG’s Solution for the Mexican Client

After understanding the client’s needs, we recommended the paper cup printing machine best suited to their production model and provided a complete solution.

✔ 1. Adoption of Flexographic Printing Machine Solution

We selected YG’s 4-color flexographic printing machine for the client for the following reasons:

- Suitable for high-volume paper cup pattern printing

- Uses food-grade water-based ink, environmentally friendly and compliant with Mexican regulatory requirements

- High color saturation and good stability

- Suitable for PE coated paper, i.e., paper cup fan raw material

- Perfectly compatible with their existing paper cup machine

Printing speed reaches 60–120 meters/minute, fully meeting the paper cup production volume of a medium-sized factory.

✔ 2. Upgraded Printing Process to Improve Paper Cup Machine Production Efficiency

YG engineers calibrated the printing machine speed according to the client’s paper cup machine speed, ultimately achieving:

- Printing machine speed ≥ Paper cup forming machine speed

- No material jamming, misalignment, or curling issues

- Consistent printing color and cup shape formation

The client was very satisfied because the previous “printing bottleneck” problem was completely eliminated.

✔ 3. Provided Color Management and Sample Testing Services

The Mexican client was most concerned about color difference issues, so we provided:

- High-precision registration system

- Color calibration and debugging

- Free printing samples

- Recommended matching inks

High consistency in sample coloring, which was highly appreciated by the client.

✔ 4. Fast After-Sales Response + Spare Parts Inventory Support

Mexican users highly value after-sales service, and we promised:

- Technical response within 24 hours

- Spare parts in stock (shipped via DHL)

- Provided local Mexican engineer cooperation resources

- Provided remote installation video guidance

The client said: “This is one of the key reasons why we chose YG.”

Mexican Client Usage Feedback

Client feedback is as follows:

- Significant improvement in printing quality

- Doubled capacity for large order fulfillment

- New equipment investment can be recouped in 6–12 months

- Attracted more catering brands to place orders

One feedback statement is particularly typical:

“Our factory previously had difficulty handling large coffee chain orders. Now, the printing quality exceeds customer expectations, and order volume has doubled.”

FAQs Most Concerned by Mexican Clients

- Is a flexographic printing machine or a digital printing machine more suitable for Mexico?

- Large volume → Flexographic printing machine

- Small volume, multiple patterns → Digital printing machine

Most Mexican clients choose flexographic printing machines because of their lower cost and higher output.

2. How much does a paper cup printing machine cost?

The price varies depending on the number of colors, speed, and configuration. Contact us for more details now! [WhatsApp/WeChat/Phone] +86 13837115193.

- Is it necessary to purchase the paper cup forming machine together with the printing machine?

They can be purchased separately, but for a stable production line, we recommend:

Printing machine + Slitting machine + Die-cutting machine + Paper cup forming machine (highest compatibility for the entire line)

- Can the printing machine use food-grade ink?

Yes. All of YG’s flexographic printing machines support food-grade water-based ink.

- Can it print coffee cups, beverage cups, and ice cream cups?

Yes. This machine is suitable for various PE-coated paper cup base papers.

higher-quality paper cup production capabilities.

The success story of our Mexican client once again proves that paper cup printing quality determines whether paper cup products can truly enter the high-end market. A stable, high-precision paper cup printing machine not only affects the pattern effect but also directly relates to the forming quality, production efficiency, and ultimate market acceptance of the paper cups.

As a professional paper cup equipment supplier, YG Machinery provides a complete set of production solutions from printing, slitting, and die-cutting to paper cup forming machines, ensuring precise matching and long-term stable operation of the entire production line. Whether it’s improving printing quality, meeting brand customization needs, expanding production capacity, or increasing ROI, YG can provide mature, reliable, and globally proven technical support.

Choosing YG means choosing higher production efficiency, lower operating costs, and more competitive paper cup products.

If you need recommendations for printing machines or complete paper cup production lines more suitable for factories with different production volumes and budgets, I can also provide customized solutions for you.