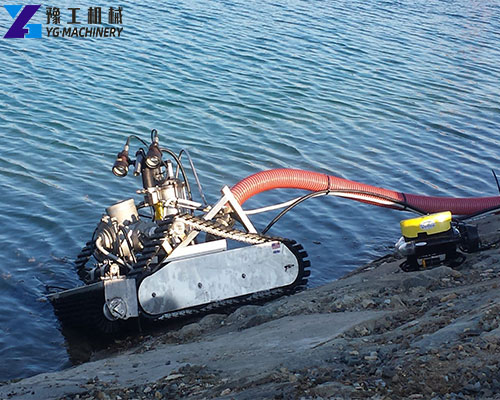

Recently, an Australian chemical company purchased an intelligent dredging robot for cleaning accumulated scale and sludge in its plant area. This robot is specially equipped with an explosion-proof motor and features a tracked walking design, allowing for flexible movement in complex environments. Customer feedback indicates that the equipment is portable, safe, easy to operate, significantly improves work efficiency, and greatly reduces human risk.

Intelligent Dredging Robot Parameters

| Parameter | YG500 | YG600 | YG700 | YG800 | YG900 | YG1200 |

| Robot Dimensions (mm) | 1500*500*650 | 1500*600*650 | 1600*700*650 | 1600*850*700 | 1650*960*750 | 1900*1200*750 |

| Dredging Width (mm) | 500 | 600 | 700 | 800 | 900 | Suitable for large culverts |

| Travel Speed (m/s) | 3–15 | 3–15 | 3–15 | 3–15 | 3–15 | 0–17 m/min |

| Pump Diameter (inch) | 3 | 3 | 4 | 4 | 4 | 4or6 |

| Pump Flow (m³/h) | 100 | 100 | 160 | 160 | 200 | 250 |

| Pump Head (m) | 0–30 | 0–30 | 0–25 | 0–25 | 0–25 | 0–30 (Horizontal: 100–150m) |

| Hydraulic Station Dimensions (mm) | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2120*1240*1200 |

| Main Motor Power (kW) | 18 | 18 | 22 | 22 | 22 | 45KW (50KW) or Diesel 76KW (123KW) |

| Hydraulic System Pressure (Mpa) | 0–16 | 0–16 | 0–16 | 0–16 | 0–16 | Not specified |

| Particle Size (mm) | 15 | 15 | 40 | 40 | 50 | 0–40 (customizable) |

| Winch Speed (r/min) | 0–10 | 0–10 | 0–10 | 0–10 | 0–10 | 0–10 |

| Pipe Length (m) | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30m/pack, 20kg pressure resistant, optional |

| Control System | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote |

| Lighting System | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 |

Common Demand for Intelligent Dredging Robots among Australian Customers

In Australia, the industrial, environmental, and water sectors commonly face the following challenges:

- Chemical plant and oil tank sediment cleaning is difficult and dangerous.

- Traditional manual cleaning is high-risk and inefficient.

- Lake, river, and port sludge removal requires environmentally friendly and efficient solutions.

- High requirements exist for underwater operation, remote control, safety, and visual monitoring.

This situation has led an increasing number of Australian customers to seek intelligent dredging robot solutions to reduce human entry into hazardous areas while improving operational efficiency and environmental standards.

YG’s Professional Solutions for Chemical Plant Deposits

To meet the Australian market’s demand for efficient, safe, and intelligent dredging, YG has introduced several innovative designs:

✔ Crawler Dredging Robot

- Adaptable to chemical plant surfaces, wetlands, lakes, and complex waterways

- Ensuring stable movement of the robot in muddy or sloping environments

✔ Explosion-proof Motor and Safety Design

- Meets the requirements of chemical plants and high-risk areas

- Sealed, anti-static, and spark-proof electrical control box

✔ Remote Control Dredging Robot

- Operators can perform the entire operation from a safe area

- Control pump flow, propulsion, direction, and underwater camera

✔ Visual Monitoring

- High-definition underwater camera + LED lighting

- Real-time monitoring of sludge thickness and dredging progress

- Improved construction accuracy and reduced rework rate

✔ High-efficiency Sludge Transport Robot

- Quickly transports dredged sludge or sediment to designated areas

- Improved dredging efficiency and reduced manual handling costs

✔ High cost-effectiveness of investment

- High degree of automation; one machine can replace multiple workers

- Long lifespan and simple maintenance

- Total cost lower than long-term manual labor or traditional dredging machinery

Feedback from Australian customers on the dredging robot

Several Australian customers have stated after using the YG intelligent dredging robot:

- Chemical plant sediment removal speed increased by approximately 50%

- High-risk manual operations were avoided

- The underwater dredging robot operates stably in deep water or difficult-to-access areas

- The sludge transport robot offers high transport efficiency and less clogging

- Remote control and visualization systems make operations more precise and reliable

Customers generally believe that this equipment not only saves manpower but also reduces accident risks, making it an ideal choice for long-term investment. Dredging robots are used in Europe to remove silt from lakes, and they are very effective.

FAQs most frequently asked by Australian customers

1) Can it be used in chemical plants and oil tanks?

Yes. The equipment can be equipped with explosion-proof motors and sealed electrical control systems to ensure safety.

2) Is it suitable for lake, river, or wetland cleaning?

Yes. As an underwater dredging robot, it can operate underwater, combining environmental friendliness and high efficiency.

3) What is the sludge transport capacity?

The built-in sludge transport robot system can quickly transport sludge to designated locations, reducing blockages.

4) Is it difficult to operate?

Not difficult. With the remote-controlled dredging robot system, operators can complete dredging without entering hazardous areas.

5) Is the maintenance cost high?

Simple maintenance, low cost of wear parts, and overall cost is lower than long-term manual or traditional dredging solutions.

Why do Australian customers choose YG Machinery?

- Professional manufacturing experience: 10+ years of R&D experience in intelligent dredging robots;

- Verified by multiple successful cases in Europe and Australia;

- Supports explosion-proof, remote control, tracked, and visualized operation;

- Fast return on investment: High efficiency, low maintenance, reduced labor;

- Comprehensive after-sales service: Remote technical support, installation guidance, spare parts supply.

YG intelligent dredging robot has become the preferred solution for dredging projects in Australian chemical plants, lakes, and rivers, achieving safe, efficient, and intelligent operations.