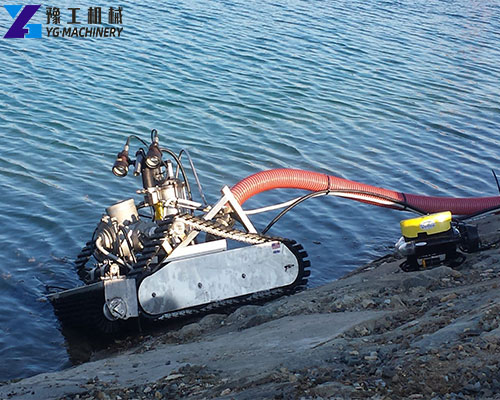

In 2025, customers from several European countries, including Poland, Spain, France, and Italy, purchased YG’s crawler dredging robot, primarily for lake silt treatment, urban waterway maintenance, wetland dredging, and ecological restoration projects. The equipment performed stably in outdoor environments across Europe, demonstrating high dredging efficiency and operational safety. Customer feedback indicated that “one machine can replace 6-10 workers,” with overall results being excellent.

Crawler Dredging Robot Parameters

| Parameter | YG500 | YG600 | YG700 | YG800 | YG900 | YG1200 |

| Robot Dimensions (mm) | 1500*500*650 | 1500*600*650 | 1600*700*650 | 1600*850*700 | 1650*960*750 | 1900*1200*750 |

| Dredging Width (mm) | 500 | 600 | 700 | 800 | 900 | Suitable for large culverts |

| Travel Speed (m/s) | 3–15 | 3–15 | 3–15 | 3–15 | 3–15 | 0–17 m/min |

| Pump Diameter (inch) | 3 | 3 | 4 | 4 | 4 | 4or6 |

| Pump Flow (m³/h) | 100 | 100 | 160 | 160 | 200 | 250 |

| Pump Head (m) | 0–30 | 0–30 | 0–25 | 0–25 | 0–25 | 0–30 (Horizontal: 100–150m) |

| Hydraulic Station Dimensions (mm) | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2120*1240*1200 |

| Main Motor Power (kW) | 18 | 18 | 22 | 22 | 22 | 45KW (50KW) or Diesel 76KW (123KW) |

| Hydraulic System Pressure (Mpa) | 0–16 | 0–16 | 0–16 | 0–16 | 0–16 | Not specified |

| Particle Size (mm) | 15 | 15 | 40 | 40 | 50 | 0–40 (customizable) |

| Winch Speed (r/min) | 0–10 | 0–10 | 0–10 | 0–10 | 0–10 | 0–10 |

| Pipe Length (m) | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30m/pack, 20kg pressure resistant, optional |

| Control System | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote |

| Lighting System | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 |

The Current State of Silt Removal for European Clients

EU countries generally emphasize ecological protection and water health, but the reality presents local contractors and government water departments with numerous challenges, including:

- Persistent siltation in rivers, lakes, and ports, impacting water flow and ecosystems.

- Traditional manual or excavator-based silt removal is costly and slow.

- Many bodies of water require shallow or underwater operations, making it difficult for machinery to access them.

- Minimizing disturbance and turbidity is crucial for ecological protection.

- Some factories or industrial settings require sludge cleaning robots that do not require personnel.

- Urban landscape lakes must achieve low noise, low emissions, and safe operation.

These challenges are driving an increasing number of European clients to turn to highly automated, low-manpower, remotely controlled robotic dredge equipment. YG’s crawler dredging robot perfectly addresses these needs.

YG’s Professional Solutions for European Projects

To meet the environmental standards, safety requirements, and complex water conditions of the European market, YG offers the following configurations and services:

✔ Crawler Mobility

- Supports complex terrains such as silt, wetlands, shallow water, and gravel.

- Avoids sinking into soft mud, improving construction continuity.

- Suitable for projects in lakes, rivers, and swamps.

✔ Remote Control System (Zero-Entry Safety)

- Allows operators to maintain full control from a safe area.

- Controls propulsion, sludge pump, underwater camera, and direction.

- Suitable for rivers, lakes, chemical plants, and hazardous water tanks.

✔ Real-Time Visual Monitoring

- Underwater camera + LED lights.

- Real-time monitoring of underwater silt thickness and cleaning speed.

- Improves construction accuracy and reduces rework.

✔ Multiple Power Options (including explosion-proof motors)

- European customers can choose between electric and diesel drive.

- Some Spanish chemical users have opted for explosion-proof motors, suitable for industrial sludge tanks.

- Also usable as a sludge cleaning robot. Used in factory sedimentation tanks and wastewater ponds

✔ Compatible with various pump types and operating conditions

- Can be used as a river silt cleaning machine for cleaning lakes, rivers, and wetlands

- Can be used as an underwater dredging robot for continuous underwater operation

- High-flow pump + anti-clogging structure, suitable for thick silt

✔ High ROI

- One machine replaces multiple workers

- Saves labor and reduces downtime

- Long service life and simple maintenance

European customers generally report: Investment can be recovered in about one year

European customer feedback: Significant results, low cost, and high environmental friendliness

Customers from Poland and Italy stated:

- Lake treatment area is larger, efficiency is increased by 40-60%;

- Underwater dredging robot is more stable than manual in deep water areas;

- In river treatment, silt transport is smooth and clogging is extremely low;

- Electric drive is more environmentally friendly and quieter;

- Visual system makes operation more precise.

Many customers also emphasize that YG’s crawler dredging robot is easy to maintain, has low spare parts cost, and is ideal for long-term projects. In addition, our customers in Nigeria and South Africa have also found that the dredging robots are very effective at cleaning oil tank deposits and lake silt.

FAQs from European Customers

1) Can the equipment operate underwater? Is it stable?

Yes. As an underwater dredging robot, it can operate stably in water depths of 1–12 meters.

2) Can it be used for ecological dredging of rivers or lakes?

Yes. It is also a compliant river silt cleaning machine, suitable for cleaning sediments such as silt, algae, and humus.

3) Does it meet EU safety and environmental requirements?

YG can configure CE certification, noise limits, electric drive systems, and explosion-proof solutions according to requirements.

4) Can it be used as a sludge cleaning robot in chemical plants or sedimentation tanks?

Yes. Optional explosion-proof motors, remote control, and sealed electrical control boxes are available, suitable for high-risk areas.

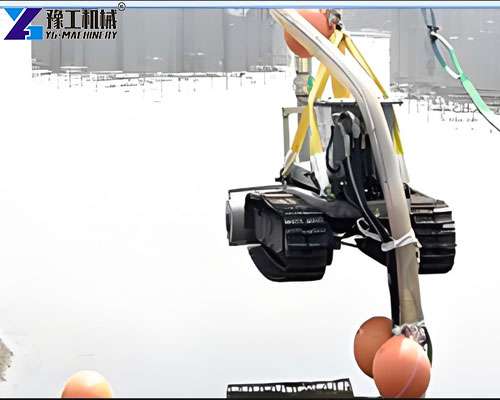

5) Is it difficult to transport to Europe?

YG provides complete wooden crate export packaging, full CE documentation, fast customs clearance, and supports remote installation guidance.

6) What are the service life and maintenance costs?

With a main structure lifespan of 10+ years, inexpensive wear parts, and simple pump system maintenance, the overall cost is significantly lower than that of European equipment.

Why are more and more European customers choosing YG?

- 10+ years of focused manufacturing of dredging and environmental protection equipment;

- Multi-country case studies (Poland, Spain, France, Italy, Germany);

- Supports high European requirements such as CE certification, electric drive, explosion-proof, and remote control;

- High degree of automation, saving labor costs;

- Fast logistics + English/Russian/Spanish technical support.

YG’s crawler dredging robot is gradually becoming the preferred equipment for water dredging, environmental remediation, and industrial sludge pumping in Europe.