Paper cup machine for sale, also known as paper cup forming machines, are special equipment for producing disposable paper cups. It converts the roll base paper into disposable paper cups for daily use through a series of precision processes. Such as slitting, flexographic printing, roller creasing, curling shaping, and bottom cover bonding. The single-layer paper cups produced by ordinary paper cup machines are light and portable. It is suitable for temporary beverages in fast food restaurants. Our paper cup machines can also produce double-layer paper cups with heat-insulating corrugated layers when combined with laminating machines. Whether it is daily drinking water in the office or the popular product packaging of milk tea shops, there are paper cup machines behind them. If you want to start a paper cup machine business. Click to get the latest quotation!

paper cup machine for sale parameter

| Model | YG-M100 |

| Paper Cup Size | 3-16 OZ |

| Raw Material | One-side or two-side PE coated paper(Singe PE or Double PE coated paper) |

| Speed | 80-100pcs/min |

| Suitable paper weight | 160-260g/㎡;±20g/㎡ |

| Voltage supply | 380V(220V) 50HZ |

| cup size | bottom28-54mm,top40-75mm,high30-95mm |

| Working Air Source | 0.4-0.6Mpa; 0.4m³/min |

| General power | 4.5kw |

| Net weight | 1500kg |

| Cup Side Sealing | Ultrasonic |

| Bottom Knurling | HOT AIR SYSTEM |

| We can customize the machine and mold according to the customer’s requirements!!! | |

Customer application of paper cup forming machines

- A fast food chain giant in California, USA, purchased 2 YG-DP10 high-speed paper cup machines for sale. And set up an automated production line. According to feedback from the person in charge, the equipment has been running continuously for 12 months without major repairs. With the intelligent early warning system, 80% of potential failures can be avoided in advance, and maintenance costs can be saved by nearly 30%.

- A creative paper product studio in London, UK, uses a fully automatic paper cup machine. They use it for customize wedding and party paper cups. They use the equipment to quickly change molds and launch paper cups of 5 different sizes. And 8 personalized patterns within a week, which has triggered a wave of communication on social platforms. And the order volume has increased by 200% year-on-year.

- An environmental protection company in Vancouver, Canada, supplies more than 100 local coffee shops and milk tea shops with the help of YG paper cup machines. The operator said that the equipment operation interface is simple and intuitive, and new employees can work independently after only 2 hours of training. The production efficiency is 15% higher than that of similar equipment, and the cost can be recovered and profitable within half a year.

advantages of YG disposable paper cup making machines

- YG paper cup machines are very cost-effective! Compared with similar products, the price has dropped by 20%, but the performance is not inferior.

- The equipment is equipped with an AI intelligent control system and built-in 200+ fault diagnosis models. Once an abnormality occurs, the problem can be accurately located within 3 seconds and an alarm will be automatically issued.

- The exclusive patented quick-release mold structure can switch between different cup types in 3 minutes without any tools. It is suitable for a full range of paper cup specifications from 3 ounces to 16 ounces.

- There is a breakthrough in energy saving. It uses servo motor drive and energy recovery technology, which saves 30% of electricity compared with traditional equipment.

- Whether it is a small family workshop or a large factory with an annual output value of over 100 million, you can find a cost-effective paper cup production solution in YG.

YG’s hot-selling fully automatic paper cup machine models

Looking for paper cup machine for sale, these three hot-selling models of YG are not to be missed!

- DP10 paper cup machine, a cost-effective choice, produces 80-110 paper cups per minute, and can produce 2-9 ounce paper cups. It is simple and easy to operate, especially suitable for small businesses to start using.

- DP106 fully automatic paper cup machine, upgraded performance, can reach a production of 70-90 paper cups per minute. It can produce 2-16 ounce paper cups. Equipped with an intelligent monitoring system, it can control the production quality in real time and easily cope with larger paper cups to meet different customer needs.

- GS120 high-speed paper cup machine, industry-leading level, produces 100-120 paper cups per minute, supports rapid switching of multiple cup types, adapts to large-scale production needs, and is a powerful assistant for large-scale paper cup manufacturers to expand the market. These three paper cup forming machines will help you quickly open up the paper cup machine business and seize market share. Click to consult and get exclusive quotes!

Working principle of paper cup forming machine

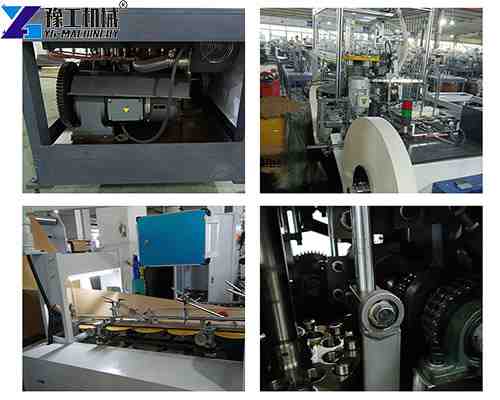

The paper cup machine works in coordination with mechanical transmission and automatic control.

- Taking the fully automatic paper cup machine as an example, the paper feeding device driven by the motor first feeds the roll base paper into the printing unit to complete the brand pattern and text printing.

- Then enter the cutting station, and the high-precision circular knife cooperates with laser positioning to cut the paper into the cup body and cup bottom.

- Then, in the forming mold, the curling and bottom sealing processes are completed through high-temperature hot pressing and air pressure forming technology.

- Finally, the cup discharge device composed of vacuum suction cups neatly stacks and sends out the finished paper cups.

What is the process flow of the paper cup machine?

- The first step is to cut the base paper, and cut the 1.5-meter-wide roll base paper into narrow paper strips suitable for production, with an error control of ±0.5mm.

- The second step is flexographic printing, using environmentally friendly water-based ink, and presenting high-resolution patterns through four-color overprinting technology.

- The third step is curling molding, using a rotary mold and an air pressure device to roll the paper strip into the shape of the cup body, and at the same time forming an anti-scalding curling edge.

- The fourth step is cup bottom molding, punching the cut round paper into a bowl-shaped cup bottom.

- The fifth step is to bond the bottom, and firmly combine the cup body and the cup bottom through hot melt adhesive or ultrasonic welding technology.

- The finished products are collected at last, and the qualified paper cups are stacked and packaged by the robotic arm.

professional paper cup making machine manufacturer-YG

The current paper cup machine market is booming, and the demand for paper cup machine for sale continues to grow. YG has been deeply involved in the industry for 15 years and has provided more than 1,000 paper cup production equipment to customers in more than 80 countries around the world. From site planning, equipment selection, to installation and commissioning, employee training, to after-sales maintenance, we provide one-stop service. In response to different customer needs, whether it is a micro production line with a daily output of 5,000 paper cups or a smart factory solution with a daily output of 1 million, we can provide exclusive paper cup forming machines solutions. Don’t hesitate, choose YG paper cup machine and start your efficient production journey! Click on the official website to consult now to get detailed quotes and customized solutions!