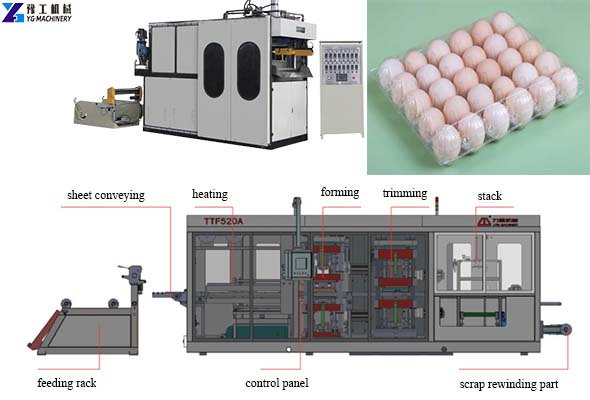

The plastic egg tray making machine is a high-speed blister-forming machine controlled by a computer. It has the functions of automatic heating, forming, punching, cutting, stacking, counting, and so on. This plastic container machine has a very wide range of applications, it is used in the packaging of food, electronics, medicine, industry, and other fields. The egg tray thermoforming machine has a humanized mold replacement structure, which can greatly shorten mold replacement time. And it also needs to be equipped with a hydraulic cutting machine to complete the entire blister process.

Application Range

The egg tray thermoforming machine is widely used for processing PS, PET, PP, PVC, ABS, HIPS, and other plastic sheets. It can produce various bowls, dishes, lids, trays, and other blister packaging products by mold forming and cutting.

Plastic Egg Carton Making Machine Working Video

Plastic Egg Carton Packaging

Both plastic egg trays and pulp egg trays are designed to protect egg packaging during egg transport. It’s just that the materials used are different. The plastic egg trays produced by plastic egg tray making machines are widely used in the packaging of many kinds of eggs. Such as Eggs, duck eggs, quail eggs, pigeon eggs, etc. It meets the various needs of customers, from 1 to 35 egg trays, and can be processed. Compared with pulp egg trays, plastic egg trays have lids, which can meet the needs of terminal retail packaging.

Parameters of Plastic Egg Tray Machine

| Number of stations | Four stations | Three stations | Four stations | Three stations |

| Model | YG-700AF | YG-700A | YG-520AF | YG-520A |

| Maximum molding area | 700*600mm | 700*600mm | 520*400mm | 520*400mm |

| Maximum forming depth | 135mm | 135mm | 110mm | 110mm |

| Sheet thickness | 0.2-2.0mm | 0.2-2.0mm | 0.2-2.0mm | 0.2-2.0mm |

| Maximum forming speed | 30batch/min | 30batch/min | 30batch/min | 30batch/min |

| Air pressure | 0.6-0.8mpa | 0.6-0.8mpa | 0.6-0.8mpa | 0.6-0.8mpa |

| Air consumption | 3.6m³/min | 3.6m³/min | 3.0m³/min | 3.0m³/min |

| Water Consumption | 0.7m³/h | 0.7m³/h | 0.7m³/h | 0.7m³/h |

| Maximum sheet width | 730mm | 730mm | 570mm | 570mm |

| Applicable sheet | PP,PS,HIPS,PET,PVC,PLA etc. | PP,PS,HIPS,PET,PVC,PLA etc. | PP,PS,HIPS,PET,PVC,PLA etc. | PP,PS,HIPS,PET,PVC,PLA etc. |

| Power supply | 380V, 50Hz | 380V, 50Hz | 380V, 50Hz | 380V, 50Hz |

| Use power | 105Kw | 95Kw | 55Kw | 50Kw |

| Rated power | 210Kw | 190Kw | 110Kw | 100Kw |

| Heating power | 118Kw | 118Kw | 75Kw | 75Kw |

| Process | Forming – Punching – Trimming – Stacking | Forming – Punching – Trimming – Stacking | Forming – Punching – Trimming – Stacking | Forming – Punching – Trimming – Stacking |

| Size | 13000*4700*2750mm | 11500*4700*2750mm | 11000*4600*2700mm | 9700*4600*2700mm |

| Weight | 25T | 19T | 11T | 9T |

The above are the parameters of the three-station and four-station egg tray thermoforming machines, which are applicable to different maximum sheet widths and forming depths. Please send us the size of the egg tray you want to make or the egg diameter and we will recommend the right equipment for you.

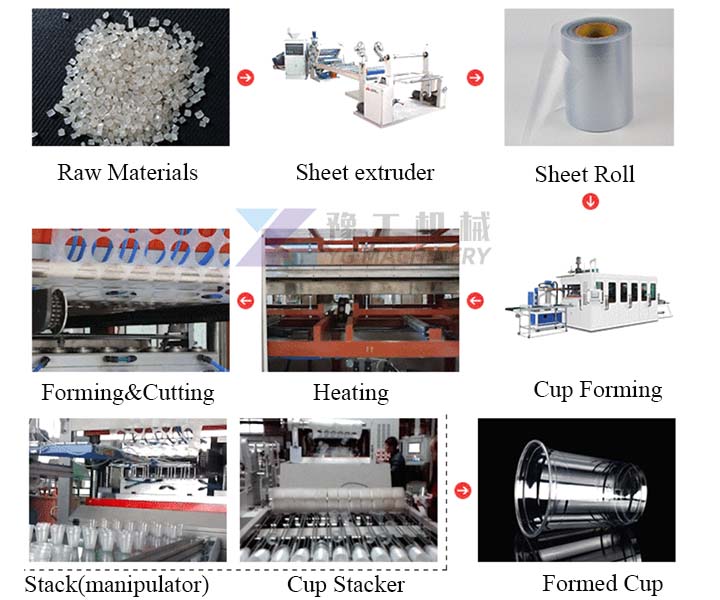

Plastic Egg Tray Production Process

The plastic egg tray forming is similar to the plastic cup forming by the plastic cup making machine. The production of plastic egg trays has roughly gone through forming, heating, plastic forming, edge trimming, stacking, and finished products. Among them, molding, heating, and plastic forming need to be completed on the plastic egg tray making machine. In addition, it requires an additional precision four-column hydraulic trimmer for edge trimming. If egg trays need to be stacked, then need a stacker for stacking. Also, if you want to start with plastic pellets, then you need a plastic sheet extruder to make the plastic pellets into sheet rolls. The sheet roll is then put into a plastic egg tray machine for blister forming.

Egg Tray Thermoforming Machine Configuration Sheet

| 1. Positive and negative pressure forming device | 2. Vacuum forming device |

| 3. Air control device | 4. Touch screen computer temperature module point-to-point control function |

| 5. Cooling Device | 6. Knife mold, mold temperature control device |

| 7. Automatic punching and cutting function | 8. Automatic stack count function |

| 9. Edge material automatic winding function | 10. Safety guard |

Features of Plastic Egg Tray Making Machine

- Adopt all servo control systems and advanced supporting equipment, suitable for sheet processing of various materials.

- The mold replacement is more convenient, greatly shortening the mold replacement time, and meeting the needs of customers who want to use one piece of equipment to make a variety of products.

- It has an advanced heating system and adopts an intelligent module to control temperature, with a fast response and short time.

- Stainless steel heat shield design, fast heat dissipation, lightweight, and low cost.

- The heater adopts an infrared radiation heater, which has fast heating, stability, and high precision.

- The servo drive makes it easier to control the speed of the upper and lower dies so that the upper and lower dies are more powerful and run smoothly up and down.

- Equipped with thermal protection device to prevent damage to the equipment due to overload and overcurrent due to long-term operation of the motor, and ensure the smooth operation of the equipment.

Other Plastic Thermoforming Products

The multi-functional plastic tray thermoforming tray machines provided by YG thermoforming machine manufacturers meet the production needs of different customers. You can use this equipment to produce egg trays, fruit trays, plastic cups, plastic cup lids, plastic lunch boxes and many other products. In addition, YG also provides a variety of food container production equipment such as paper cup machines, paper bowl machines, aluminum foil food container making machines, and paper lid machines. If you need food container production equipment, please leave us a message.